A Beginner’s Guide to Understanding CMMS and Its Benefits

Discover the essentials of CMMS, its advantages in maintenance management, and how it enhances asset tracking and compliance.

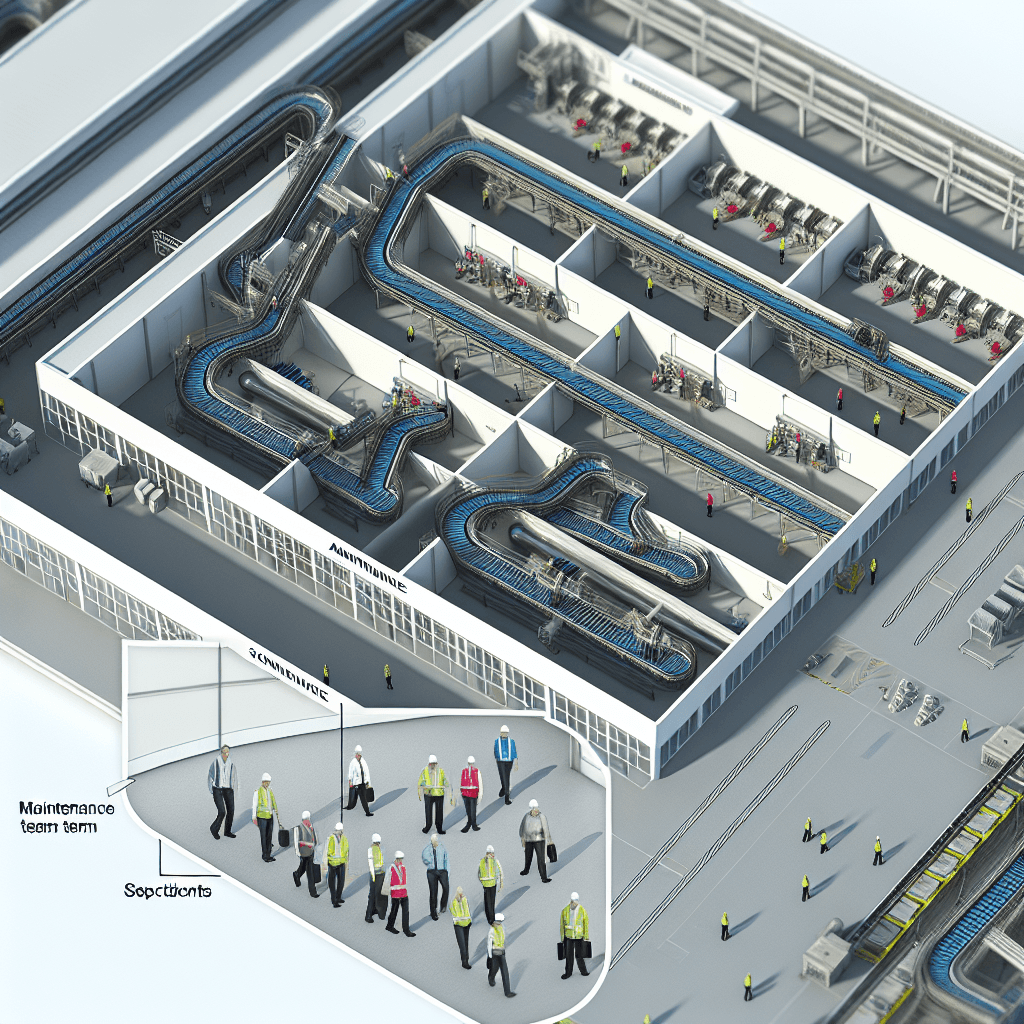

MaintainNow Team

July 23, 2025

In the fast-paced world of maintenance management, understanding the tools at our disposal can make a remarkable difference in operational efficiency. For those new to the field, the term Computerized Maintenance Management System (CMMS) may sound daunting. However, this powerful tool is designed to streamline your maintenance operations, improve asset tracking, and ensure compliance while supporting your overall maintenance strategy. In this comprehensive guide, we'll explore the fundamentals of CMMS, its benefits, and real-world applications that can transform your maintenance management processes.

Understanding CMMS: The Basics

To start, let’s break down what a CMMS actually is. At its core, a CMMS is software that centralizes maintenance management tasks and provides a systematic approach to managing work orders, asset tracking, and compliance. In my experience, companies that implement a CMMS often see a significant reduction in downtime and an increase in overall productivity.

Think of CMMS as your maintenance team's command center. It allows you to track asset performance, schedule preventive maintenance, and analyze data to make informed decisions. Whether you are managing a fleet of vehicles, manufacturing equipment, or facilities, a CMMS can be tailored to meet your specific needs.

Benefits of Implementing a CMMS

Now that we've established what a CMMS is, let’s dive into the benefits it offers.

1. Enhanced Work Order Management

One of the primary functions of a CMMS is to manage work orders efficiently. This feature allows maintenance professionals to create, assign, and track work orders in real-time. For instance, I’ve seen organizations that used to rely on paper-based systems struggle with lost requests and miscommunication. With a CMMS, work orders are documented electronically, making it easier for technicians to receive updates and complete tasks promptly.

Imagine a scenario where a critical piece of machinery breaks down. With a CMMS, you can instantly generate a work order, assign it to the right technician, and track its progress from start to finish. This streamlined approach not only minimizes downtime but also enhances accountability within the team.

2. Improved Asset Tracking

Asset tracking is another critical aspect of maintenance management that a CMMS excels at. By keeping a detailed inventory of all assets, including their maintenance history, you can easily track performance and identify trends. This information is invaluable when deciding whether to repair or replace equipment.

For example, I worked with a manufacturing plant that struggled with excessive maintenance costs due to aging equipment. By utilizing their CMMS for asset tracking, they discovered that several machines were no longer cost-effective to maintain. Armed with this data, management made informed decisions about asset replacement, leading to significant savings and improved efficiency.

3. Compliance Made Easy

In industries where compliance with safety regulations is paramount, a CMMS can be a lifesaver. The system helps ensure that maintenance tasks are completed according to regulatory standards. I’ve seen companies that faced hefty fines due to non-compliance with safety regulations. By integrating compliance tracking into their CMMS, they were able to automate reminders for inspections and maintenance tasks, significantly reducing the risk of violations.

Additionally, a CMMS can generate reports that demonstrate compliance, making it easier to provide documentation during audits. This level of organization not only protects your company from potential legal issues but also enhances your reputation in the industry.

4. Data-Driven Decision Making

Another advantage of using a CMMS is the wealth of data it collects and analyzes. By harnessing this data, maintenance professionals can identify patterns, predict equipment failures, and optimize maintenance strategies.

For instance, in my tenure at a utility company, we implemented a CMMS that tracked the performance of our generators. The data revealed that specific components were prone to failure after a certain number of operational hours. Armed with this insight, we adjusted our preventive maintenance schedule to address these components before they caused significant downtime. The result? A more reliable power supply and a happier customer base.

Choosing the Right CMMS: A Focus on MaintainNow

When it comes to selecting a CMMS, there are numerous options available, but not all are created equal. One solution that stands out in the industry is MaintainNow. This application offers a user-friendly interface and robust features that address the challenges we've discussed.

MaintainNow provides seamless work order management, asset tracking capabilities, and compliance monitoring, all in one platform. The application is designed to empower maintenance teams by simplifying their workflows and enhancing collaboration. If you’re looking to implement a CMMS, I highly recommend checking out MaintainNow at https://maintainnow.app.

Real-World Applications of CMMS

Now that we’ve covered the basic benefits of CMMS, let’s look at some real-world applications that illustrate its effectiveness in various industries.

Manufacturing: In a manufacturing setting, equipment downtime can be particularly costly. Implementing a CMMS allows for predictive maintenance strategies, which help schedule maintenance before equipment failures occur. A case study with a leading automotive manufacturer showed that they reduced unexpected downtime by 30% within the first year of CMMS implementation.

Healthcare: In healthcare, maintaining medical equipment is vital for patient safety. A hospital that implemented a CMMS was able to automate their work orders for equipment inspections and repairs. This not only improved compliance with health regulations but also ensured that critical equipment was always operational when needed.

Facilities Management: For facilities managers, a CMMS can streamline maintenance tasks across multiple locations. One property management company utilized a CMMS to manage maintenance requests from tenants. By automating the process, they improved response times by 40%, leading to higher tenant satisfaction.

Conclusion: The Path Forward with CMMS

In conclusion, understanding CMMS and its benefits is crucial for anyone involved in maintenance management. From enhancing work order management to improving asset tracking and ensuring compliance, the advantages of implementing a CMMS are clear. As maintenance professionals, we must leverage these tools to optimize our maintenance strategies and drive efficiency.

If you’re considering implementing a CMMS, take the time to evaluate your organization's specific needs. Explore options like MaintainNow, which can help you navigate the complexities of maintenance management effectively.

Remember, a well-implemented CMMS not only saves time and resources but also enhances the overall performance of your maintenance operations. Embrace the change, and you’ll soon find that the path to efficient maintenance management is paved with informed decisions and strategic planning.