CMMS ROI: How Maintenance Software Saves Time and Money

Discover how CMMS software enhances maintenance management, reduces downtime, and boosts ROI through effective asset tracking and inventory control.

MaintainNow Team

July 23, 2025

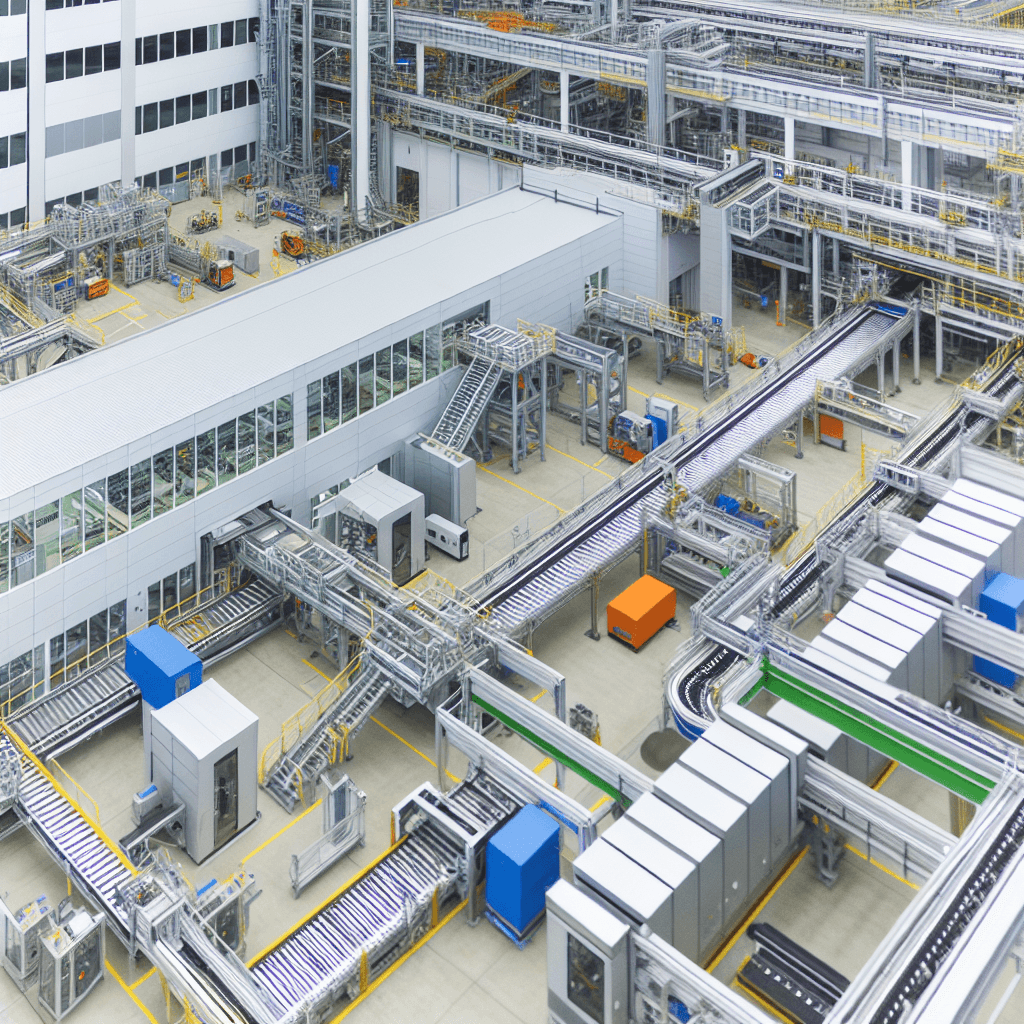

In the fast-paced world of industrial operations, the need for effective maintenance management cannot be overstated. As a maintenance professional with years of experience under my belt, I've seen firsthand how the right tools can transform operations, drive efficiency, and, most importantly, save time and money. One of the most impactful tools in our arsenal is the Computerized Maintenance Management System (CMMS).

In this blog post, we'll delve into the return on investment (ROI) of CMMS software. We'll explore how maintenance planning, asset tracking, and inventory control come together to create a streamlined maintenance process that minimizes downtime and maximizes productivity. So, if you’re considering implementing a CMMS or just looking to understand its value better, keep reading!

Understanding CMMS and Its Importance in Maintenance Management

Before we dive into the ROI, it’s essential to understand what a CMMS is and why it matters. A CMMS is a software solution designed to manage maintenance operations. It helps track assets, schedule maintenance activities, and streamline work orders, among other functions.

In my experience, the heart of any effective maintenance strategy lies in proper planning and execution. A CMMS acts as a central hub for all maintenance-related activities, allowing teams to streamline their processes and reduce the chance of errors. Think about it: without a solid maintenance management strategy and the tools to support it, organizations can struggle with unexpected equipment failures, increased downtime, and rising operational costs.

The Financial Impact of Downtime

Let’s talk about downtime—the dreaded word in the maintenance world. Downtime can have a significant financial impact on any organization. According to various industry studies, unplanned downtime can cost companies anywhere from hundreds to thousands of dollars per hour, depending on the industry and the equipment involved.

I've seen companies that faced severe losses due to equipment failures that could have been prevented with proactive maintenance planning. By implementing a CMMS, organizations can schedule regular maintenance tasks, track asset performance, and receive alerts for upcoming maintenance needs, effectively reducing the likelihood of unexpected breakdowns.

A practical example: a manufacturing facility I worked with was experiencing frequent machine failures due to a lack of proper maintenance scheduling. After introducing a CMMS, they were able to develop a comprehensive maintenance plan that included regular inspections and preventive maintenance tasks. As a result, they reduced their downtime by 30% within the first year, leading to significant cost savings.

Enhancing Asset Tracking and Management

Asset tracking is another critical component of effective maintenance management. A CMMS provides real-time visibility into asset performance, allowing maintenance teams to monitor the condition of equipment and make informed decisions regarding repairs and replacements.

Have you ever had to search through piles of paper records or spreadsheets to find information about a specific asset? It can be a frustrating and time-consuming process. With a CMMS, all asset information—such as maintenance history, warranty details, and performance metrics—is stored in one centralized location. This not only saves time but also enhances decision-making processes.

For instance, I recall a situation in which a facility was struggling with an aging piece of equipment. The maintenance team used the CMMS to analyze the asset's performance data and determine whether it was more cost-effective to repair or replace it. The insights gained from the CMMS led them to opt for a replacement, ultimately saving them from ongoing repair costs and downtime associated with that asset.

Streamlining Inventory Control

Another area where CMMS software shines is inventory control. Maintenance teams often face challenges related to managing spare parts and supplies, which can lead to delays in repairs and increased costs. A robust CMMS can automate inventory tracking, ensuring that the right parts are available when needed.

Let’s think about this for a moment: have you ever experienced a scenario where you needed a specific part for an urgent repair, only to find out it was out of stock? Not only does this delay the repair process, but it can also lead to costly downtime.

By using a CMMS, organizations can keep track of inventory levels, set reorder points, and even generate purchase orders automatically when stocks run low. I’ve personally witnessed how companies that implemented effective inventory control through a CMMS reduced their spare parts costs by as much as 25%. This improvement not only contributed to cost savings but also allowed maintenance teams to respond more quickly to equipment failures.

Real-World Success Stories and Case Studies

To further illustrate the benefits of CMMS, let’s take a look at a couple of real-world examples.

Case Study 1: A Food Processing Plant

A food processing plant was struggling with compliance issues and frequent equipment breakdowns. They decided to implement a CMMS to enhance their maintenance management practices.

Through effective maintenance planning and scheduling, the plant was able to reduce unplanned downtime by 40% within six months. Additionally, the CMMS helped them maintain compliance with food safety regulations by ensuring that all equipment was regularly inspected and maintained. The ROI from their investment in the CMMS was evident not only in reduced downtime but also in improved product quality and safety.

Case Study 2: A Large Manufacturing Facility

A large manufacturing facility was dealing with excessive maintenance costs and inefficient asset management. After implementing a CMMS, they were able to gain insights into their maintenance trends and asset performance.

The facility's maintenance team utilized the CMMS to identify underperforming assets and implement targeted maintenance strategies. This resulted in a 20% reduction in maintenance costs over a year. The CMMS also facilitated better communication among team members, improving collaboration and overall efficiency in maintenance operations.

Conclusion: The Bottom Line on CMMS ROI

In conclusion, the ROI of a CMMS extends far beyond just saving time and money. By enhancing maintenance planning, asset tracking, and inventory control, these systems empower maintenance teams to work more efficiently, reduce downtime, and ultimately drive profitability.

If you’re still on the fence about implementing a CMMS, consider this: the cost of inaction can far outweigh the investment in a robust solution. The experiences I've shared and the real-world examples illustrate the transformative power of CMMS in maintenance management.

For those ready to take the plunge, I highly recommend checking out MaintainNow. It’s an industry-leading CMMS solution that addresses the challenges we’ve discussed while providing a user-friendly interface and powerful features for maintenance professionals. You can find more information and explore how MaintainNow can fit into your maintenance strategy at https://maintainnow.app.

Remember, the right tools can make all the difference in achieving maintenance excellence. Embrace technology, invest in a CMMS, and watch your operations thrive.