Maintenance KPIs That Matter: Measuring Success After Your CMMS Implementation

Ditch the vanity metrics. Discover the essential maintenance KPIs that truly measure the success and ROI of your CMMS implementation, from wrench time to equipment reliability.

MaintainNow Team

October 10, 2025

Introduction

The switch is flipped. The data is migrated (mostly). The team has been through the training sessions. After months of planning, demos, and budget approvals, your new CMMS is finally live. There’s a collective sigh of relief, a sense of accomplishment. The endless stacks of paper work orders, the cryptic spreadsheets, and the sticky notes on the maintenance planner's monitor are gone, replaced by a clean digital interface. This is a huge win.

But after the initial celebration, a new, more pressing question starts to bubble up from the shop floor to the corner office: *So, is it working?*

It’s a fair question. A CMMS implementation is a significant investment in time, money, and political capital. The promise wasn't just to get rid of paper; it was to revolutionize the maintenance operation. To reduce downtime. To extend asset life. To get a handle on costs. Proving that return on investment, however, is where many organizations stumble. They get lost in a sea of data, tracking dozens of metrics that look good in a report but don't actually tell the story of what’s happening on the ground.

This is the critical post-implementation phase where the real work begins. It's about moving beyond simply using the software to strategically leveraging it. The key is to focus on the handful of maintenance metrics—the Key Performance Indicators (KPIs)—that genuinely reflect operational health and tie directly to the bottom line. It’s not about measuring everything; it's about measuring what matters. This is how a maintenance department transforms from a perceived cost center into a recognized value driver for the entire enterprise.

The First Hurdle: Taming the Reactive Beast

Before any sophisticated analysis of asset lifecycle cost or Overall Equipment Effectiveness (OEE) can happen, a maintenance team has to get out of what we all know as "firefighting mode." This is the state of constant, chaotic reaction. The pager goes off, a machine is down, production is screaming, and the plan for the day is immediately thrown out the window. It’s exhausting, expensive, and unsustainable. The first and most important job of a CMMS is to provide the structure needed to break this cycle. The KPIs in this phase are all about measuring that shift from chaos to control.

The Litmus Test: Planned vs. Unplanned Work

If there is one single metric that tells the story of a maintenance department's maturity, it's the Percentage of Planned Maintenance. This KPI compares the hours spent on proactive, scheduled work (preventive maintenance, planned repairs, projects) against the hours spent on reactive, emergency work.

In a purely reactive, run-to-failure environment, this ratio is often a terrifying 80% or even 90% unplanned work. Technicians are heroes, constantly swooping in to save the day, but the organization pays a steep price. Emergency repairs are exponentially more expensive than planned ones. There's the cost of lost production, the premium paid for overnight shipping on spare parts, the overtime for technicians, and the high probability of secondary damage caused by the catastrophic failure. It’s a death spiral.

The goal is to flip that ratio. A good target for a newly stabilized team is to get to 60% planned work. World-class organizations often operate at 85-90% or higher. Tracking this metric is impossible without a CMMS. It requires a clear and consistent way to code every single work order as either "planned" or "unplanned." With that simple data point captured on every job, a clear picture emerges over time. A rising percentage of planned work is the first, most tangible proof that the CMMS is delivering on its core promise. It shows a fundamental shift in strategy.

Doing What You Said You Would: PM Compliance

Simply scheduling preventive maintenance isn't enough. The work has to actually get done. PM Compliance measures the percentage of scheduled preventive maintenance work orders that are completed within a specified time frame (e.g., within the week they are due).

Before a CMMS, tracking this was a nightmare. Work orders got lost, pencil-whipped, or simply forgotten when a more "important" breakdown occurred. A modern CMMS automates this. PMs are generated automatically based on calendar time or runtime meters. They appear on a technician's schedule. Checklists are attached. When the work is done, it's closed out with a few taps.

Why does this matter so much? Because consistent PM is the bedrock of equipment reliability. Missing a simple lubrication route on a critical conveyor motor can lead to a bearing failure that shuts down an entire production line for a shift. A PM compliance rate below 80% is a red flag. It indicates that the team is still being pulled away by reactive work, that they may be understaffed, or that the PM schedule itself is unrealistic. Striving for a compliance rate of 95% or higher is the goal. This is where systems designed for the user, like MaintainNow, make a huge difference. When a technician can pull up their PMs, follow the digital checklist, and sign off on the work right from their phone at the asset, compliance rates skyrocket. There's no paperwork to lose and no reason to delay closing the loop.

Elevating the Game: Gauging True Asset Health and Reliability

Once the fires are under control and a proactive maintenance culture starts to take root, the focus can shift to more sophisticated KPIs. These are the metrics that measure not just the activity of the maintenance team, but the actual health and performance of the equipment they maintain. This is where maintenance starts to play a direct role in improving production capacity and product quality. This level of analysis is simply impossible without the rich, structured data that a well-used CMMS provides.

Mean Time Between Failures (MTBF)

Mean Time Between Failures (MTBF) is the quintessential measure of equipment reliability. In simple terms, it's the average time a piece of equipment operates before it breaks down. A higher MTBF is better; it means the asset is more reliable and fails less frequently. For example, if a critical pump runs for 2,000 hours, fails, is repaired, and then runs for another 2,500 hours before its next failure, its average MTBF over that period is 2,250 hours.

Calculating MTBF requires meticulous data tracking. You need to know the exact time an asset was put back into service and the exact time it failed. Every single time. This is where the work order system becomes a critical data repository. A CMMS captures this timestamp data automatically when a work order is opened and closed. Over time, this data allows a facility manager to see trends. Is the MTBF for our HVAC units decreasing? Why? Was there a change in our PM strategy? Did we switch to a cheaper brand of filters? These are the kinds of data-driven questions that lead to real improvements. Without a CMMS, you’re just guessing.

Mean Time To Repair (MTTR)

If MTBF measures how long things run, Mean Time To Repair (MTTR) measures how quickly the team can get them running again after a failure. It's the average time from when a failure occurs to the moment the equipment is repaired and back in service. A lower MTTR is better. It reflects the efficiency and effectiveness of the maintenance response.

MTTR is influenced by a host of factors: a technician's diagnostic skill, the availability of technical manuals and drawings, the travel time to the asset, and—critically—the availability of the correct spare parts. We've all seen a multi-million-dollar production line sitting idle for hours, even days, waiting for a $50 sensor to arrive because it wasn't in the storeroom.

A CMMS directly attacks high MTTR. Technicians using a mobile app can instantly access asset history, seeing what repairs were done in the past and what parts were used. They can pull up digital schematics and manuals on the spot. Even better, an integrated inventory module allows them to check for spare parts availability and location from their device, eliminating wasted trips to the parts crib. Tracking MTTR by asset class, and even by technician, can highlight needs for specific training or opportunities to optimize the parts inventory. The goal is to continuously shrink that repair window, which has a direct, measurable impact on plant uptime.

The Next Frontier: Predictive Maintenance

The ultimate goal is to move beyond reacting to failures (even in a planned way) and to start predicting them. This is the domain of predictive maintenance (PdM). Instead of changing the oil every 3,000 miles (preventive), you analyze the oil and change it only when it starts to show signs of breaking down (predictive). This is done using condition-monitoring technologies like vibration analysis, infrared thermography, and ultrasonic testing.

A CMMS is the central nervous system for a PdM program. The condition data from these inspections—vibration readings, temperature measurements, etc.—is logged against the asset in the CMMS. The system can then be configured to automatically trigger a work order when a reading crosses a predefined alarm threshold. For instance, when the vibration signature of a motor bearing starts to trend upwards, a work order is generated to investigate and perhaps replace the bearing during the next planned shutdown, long before it fails catastrophically. This approach maximizes asset life, minimizes repair costs, and virtually eliminates unplanned downtime from predictable failures. This is where maintenance becomes a science, driven by data, and it's a capability that modern CMMS platforms are increasingly built to support.

Speaking the Language of Business: Financial and Efficiency KPIs

A maintenance department can be doing great work, improving reliability and reducing downtime, but if that value can't be communicated to upper management in a language they understand—the language of money—then the department will always struggle for budget and resources. The final set of critical KPIs are those that translate operational improvements into financial and efficiency gains. These are the metrics that get the C-suite's attention and justify the investment in both the CMMS and the maintenance program itself.

Maintenance Cost as a Percentage of Replacement Asset Value (RAV)

This is a high-level, strategic metric used for benchmarking and long-term asset management. Maintenance Cost as a Percentage of Replacement Asset Value (RAV), sometimes called Estimated Replacement Value (ERV), compares the total annual maintenance cost for an asset (or a group of assets) to the cost of replacing it. For example, if a facility spends $50,000 per year maintaining an air handling unit that would cost $1,000,000 to replace, the maintenance cost as a percentage of RAV is 5%.

Industry benchmarks for this KPI vary, but a common target is to keep it in the 2-3% range for a well-maintained facility. A number that is too high might suggest that the team is spending too much money trying to keep old, unreliable equipment running. It might be cheaper, in the long run, to replace it. A number that is too low could be a red flag that equipment is being neglected, leading to a higher risk of major failure and deferred costs down the line. To calculate this accurately, you need a CMMS that can track all maintenance costs—labor, materials, contractors—and roll them up to the specific asset level. This data is the foundation of a sound capital planning strategy, allowing managers to make data-backed decisions about when to repair and when to replace.

The Efficiency Metric: Wrench Time

Wrench time is perhaps the most talked-about and often misunderstood efficiency metric in maintenance. It’s defined as the proportion of a technician's day that is spent directly performing work on an asset—with tools in hand. It does *not* include time spent traveling to the job, looking for information, getting permits, waiting for parts, or even talking to an operator.

The hard reality is that in a typical, unoptimized environment, wrench time can be shockingly low. Studies have shown it can be as low as 25-35%. That means for an 8-hour day, a technician might only be spending two or three hours actually performing value-added maintenance. The rest of the time is wasted on non-productive, albeit necessary, activities.

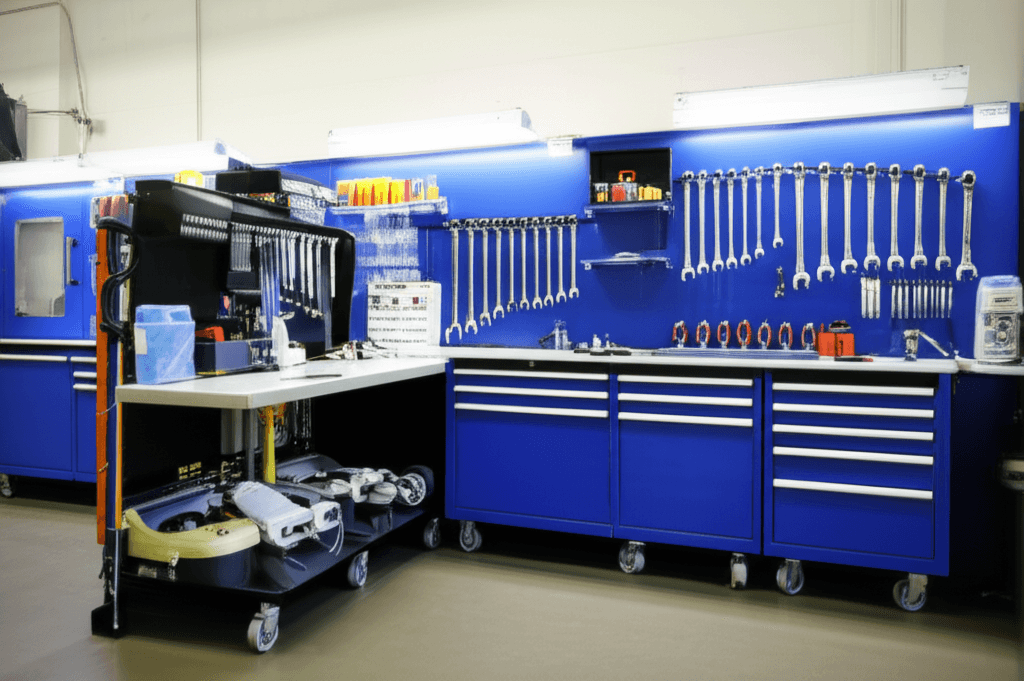

This is where a mobile-first CMMS becomes a game-changer. Think about the "before" state: a tech gets a paper work order, walks to the asset, realizes they need a schematic, walks back to the office to find it in a filing cabinet, walks back to the asset, diagnoses the problem, walks to the parts crib to see if the part is in stock, waits in line, gets the part, walks back to the asset... the wasted motion is enormous.

Now consider the "after" state with a platform like MaintainNow: the tech gets the work order on their phone. All asset history, manuals, and schematics are attached. They can see the required parts and confirm they are in stock at the parts crib before they even leave their current location. They perform the work, log their time, and close the work order—all without ever leaving the job site. The impact on wrench time is immediate and profound. Pushing wrench time from 30% to 45% is like getting an extra technician for every three you have on staff, without adding any headcount. It's a massive productivity gain hidden in plain sight, and a CMMS is the key to unlocking it.

Conclusion

Implementing a CMMS is not the finish line. It's the starting pistol. The real value isn't in the software itself, but in the operational discipline and data-driven culture it enables. Success isn't measured by the number of work orders closed, but by the tangible improvements in the KPIs that truly matter: the shift from reactive to planned work, the measurable increase in equipment reliability, and the demonstrable impact on the company's bottom line.

These metrics—Planned vs. Unplanned Work, PM Compliance, MTBF, MTTR, and Wrench Time—form a narrative. They tell the story of a maintenance organization's journey from a state of chaotic firefighting to one of strategic, proactive control. They provide the objective evidence needed to justify budgets, advocate for resources, and prove the department's value to the entire organization.

Ultimately, the CMMS is the tool that makes this all possible. It’s the single source of truth that captures the raw data from the shop floor and transforms it into actionable intelligence. The journey to maintenance excellence is a process of continuous improvement, and the data flowing through your system, accessible from anywhere via a modern interface like the one at app.maintainnow.app, is the map that guides the way. Measuring the right things is the first and most critical step on that journey.