Preventive Maintenance Software: Eliminating Unplanned Downtime and Reducing Costs

A practical guide for facility managers on using preventive maintenance software to move beyond reactive firefighting, reduce operational costs, and eliminate costly unplanned downtime.

MaintainNow Team

October 14, 2025

Introduction

The call always seems to come at 2 AM. The shrill ring of a phone cuts through the quiet, and on the other end is a frantic voice—a key production line is down, the main HVAC chiller for the data center has failed, or a critical pump has seized. For too many maintenance and facility managers, this isn't a hypothetical scenario. It’s a recurring nightmare. This is the reality of a reactive maintenance culture, a state of perpetual firefighting where the team is always one step behind the next catastrophic failure.

This "run-to-failure" model isn't just stressful; it's astonishingly expensive. The costs aren't confined to the immediate repair bill for a new motor or a set of bearings. The real damage is in the collateral—the thousands, sometimes millions, in lost production, the exorbitant overtime pay for emergency call-outs, the premium pricing on rush-ordered parts, and the ripple effect on customer commitments and supply chain integrity. It's a cycle of chaos that drains budgets, burns out skilled technicians, and puts operational goals perpetually out of reach.

The strategic migration from a reactive footing to a proactive stance, driven by robust preventive maintenance software, is no longer a forward-thinking luxury. It has become a foundational pillar of operational excellence and financial viability. It represents a fundamental shift in mindset: from fixing what's broken to ensuring it never breaks in the first place. This isn't about simply scheduling oil changes; it's about taking deliberate, data-informed control over the lifecycle and performance of every critical asset within a facility.

The Crushing Weight of a Reactive Culture

Organizations that operate in a reactive mode often normalize the chaos. The "hero" technician who can patch a broken conveyor belt with duct tape and ingenuity at 3 AM is celebrated. And while that skill is invaluable in a pinch, a facility that constantly relies on heroes is a facility that is fundamentally failing. The true costs of this operational model are insidious and spread far beyond the maintenance department's P&L statement.

Industry data consistently shows that unplanned, reactive maintenance can cost anywhere from three to nine times more than the same repair performed on a planned basis. Think about it. When a critical asset fails unexpectedly, every action is taken under duress. There's no time for proper maintenance planning. Parts are overnighted at a huge markup. Technicians are pulled from other important tasks, leading to a backlog of work. The repair itself is often rushed, leading to corner-cutting that can compromise both the quality of the work and, more importantly, the safety of the personnel involved.

Beyond the Repair Invoice: The Hidden Costs

The sticker shock of an emergency repair bill is only the tip of the iceberg. The submerged costs are what truly sink the ship.

* Operational Disruption: For a manufacturing facility, an hour of unplanned downtime on a primary production line can mean tens of thousands of dollars in lost revenue. For a commercial building, a failed HVAC system on a 95-degree day can lead to tenant complaints, broken leases, and reputational damage. This is the most visible and painful consequence.

* Cascading Failures: Equipment doesn't exist in a vacuum. A failing bearing on a motor can cause vibrations that damage connected components. A clogged filter can overwork a pump, leading to premature burnout. A run-to-failure approach ignores these interconnected relationships, allowing a minor, inexpensive issue to snowball into a major, system-wide catastrophe.

* Safety and Compliance Risks: Rushed, emergency repairs are a recipe for accidents. Proper safety protocols like Lockout/Tagout (LOTO) procedures can be overlooked in the heat of the moment. Furthermore, poorly maintained equipment is a leading cause of workplace incidents. Regulators and insurance carriers look very unfavorably on facilities that cannot demonstrate a consistent, documented maintenance program. The financial and human cost of a single safety incident can dwarf years of maintenance-related savings.

* Technician Burnout and Attrition: No one enjoys being in a constant state of emergency. Skilled maintenance technicians are a valuable, and increasingly scarce, resource. A reactive environment leads to high stress, unpredictable hours, and a sense of futility. They spend their days patching problems instead of preventing them, which erodes job satisfaction. The best technicians will eventually leave for organizations where they can apply their skills proactively, leaving behind a knowledge gap and increasing the burden on the remaining team. The so-called "wrench time"—the actual time a technician spends performing value-added work—plummets when they're constantly scrambling for parts, information, and tools.

This cycle is self-perpetuating. The more time the team spends fighting fires, the less time they have for the preventive tasks that would have stopped the fires from starting. The backlog grows, more equipment falls into a state of disrepair, and the fires become more frequent and more intense. Breaking this cycle requires a deliberate, systemic change, and that change is anchored in a modern CMMS.

The Mechanics of Proactive Maintenance: Moving Beyond the Clipboard and Spreadsheet

Making the leap to a proactive maintenance strategy sounds great in a boardroom, but for the people on the floor, the question is *how*. The answer isn't just "do more PMs." A truly effective program is a sophisticated system of data management, scheduling, execution, and analysis. Trying to manage this on paper, or even with a labyrinth of spreadsheets, is a fool's errand for any facility with more than a handful of assets. It's simply too complex, too prone to human error, and completely non-scalable.

This is where dedicated preventive maintenance software becomes the central nervous system of the entire maintenance operation. It’s the tool that transforms good intentions into consistent, repeatable, and measurable actions.

The Foundation: Knowing What You Own

You can't maintain what you don't know you have, or where it is, or what it needs. The absolute first step is building a comprehensive asset registry and hierarchy. This isn't just a list of equipment. It's a structured database. A parent asset, like a large Air Handling Unit (AHU-1), will have child assets: the supply fan, the motor, the filter banks, the cooling coils.

A modern CMMS provides the framework for this. Within a platform like MaintainNow, each asset record becomes a living digital file. It’s not just the make, model, and serial number. It’s the single source of truth, containing:

* Installation date and warranty information

* Attached O&M manuals, schematics, and P&IDs

* A complete history of all past work orders—every repair, every PM, every inspection

* A list of critical spare parts, including supplier information and stock levels

* Safety procedures specific to that piece of equipment

With this foundation, a new technician can scan a QR code on a motor and instantly pull up its entire history and the correct LOTO procedure. That's a world away from digging through a dusty filing cabinet for a faded, grease-stained manual.

Strategic Maintenance Planning: The Right Task, at the Right Time

Once assets are defined, the next step is defining the work. A robust PM program uses multiple types of triggers to generate work, moving beyond simple, time-based schedules.

* Time-Based PMs: These are the most common. *Inspect fire extinguishers every month. Lubricate motor bearings every quarter. Rebuild pump every 2 years.* These are the workhorses of a PM program.

* Usage-Based PMs: These are more dynamic and often more efficient. Instead of changing the oil in a vehicle every 3 months, you change it every 3,000 miles. For industrial equipment, this could be run-hours, production cycles, or tonnage produced. This prevents both over-maintenance (which wastes resources) and under-maintenance (which risks failure).

* Condition-Based PMs: This is where the program starts getting really smart. Instead of a fixed schedule, work is triggered by an actual measurement. *Replace filter when pressure drop exceeds X PSI. Resurface brake rotors when thickness is below Y millimeters.* This requires inspections and measurements, but it ensures that work is only done when it’s truly needed.

Software is the only practical way to manage this mix of triggers across thousands of assets. A CMMS automates the scheduling. It looks at the calendar, it tracks the runtime meter readings, and it evaluates the inspection data. It then automatically generates the work orders and assigns them to the appropriate technicians or teams, ensuring nothing ever falls through the cracks. The maintenance planning becomes automated, consistent, and reliable.

Flawless Execution with Optimized Work Orders

The automated generation of a work order is just the beginning. Its true value lies in how it empowers the technician to do the job right the first time, safely and efficiently. The difference between a poor work order ("Fix Pump 3") and a great one is staggering.

A well-structured work order within a CMMS contains everything the technician needs:

* Clear, step-by-step instructions or a checklist

* A list of required tools and materials

* Attached documents, like schematics or short instructional videos

* Critical safety protocols, warnings, and permit requirements

* Estimated time for completion

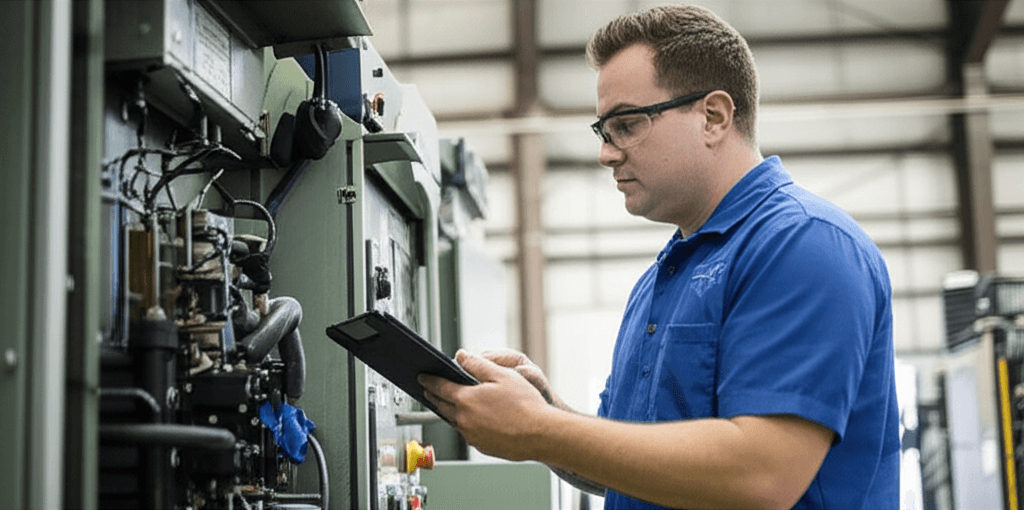

This is where mobile maintenance changes the game. Technicians are no longer tethered to a central office computer. Armed with a tablet or smartphone, they can access their assigned work directly in the field. They can view all the attached information, record their findings, log their time, and close out the work order the moment the job is done—all while standing in front of the machine. They can even take photos of a problem and attach them directly to the work order, providing invaluable context for supervisors and future troubleshooting. This seamless flow of information from the field back to the system is something paper-based systems can never achieve. Having technicians access this powerful functionality directly via a simple web interface, like the one at app.maintainnow.app, eliminates barriers and dramatically increases adoption and data accuracy.

From Preventive to Predictive: The Next Frontier in Asset Management

Preventive maintenance is a massive leap forward from a reactive state. It allows organizations to get ahead of the failure curve. But it's not the final destination. The next evolution is predictive maintenance (PdM), a strategy that seeks to perform maintenance at the exact moment it's needed—just before failure occurs.

While preventive maintenance operates on schedules (time or usage), predictive maintenance operates on real-time equipment condition. It uses technology to listen to what the assets are saying about their own health. Common PdM technologies include:

* Vibration Analysis: Detects imbalances, misalignments, and bearing wear in rotating equipment long before they become audible or catastrophic.

* Thermal Imaging: Uses infrared cameras to spot "hot spots" in electrical panels, motors, and steam traps, indicating potential failures.

* Oil Analysis: Analyzes lubricant for microscopic particles and chemical changes, revealing the internal health of engines, gearboxes, and hydraulic systems.

* Ultrasonic Analysis: Listens for high-frequency sounds that can indicate gas leaks, electrical arcing, or early-stage bearing faults.

The role of the CMMS in a PdM program is critical. It acts as the central hub where this condition data is translated into action. A sensor or an inspection might generate an alert—for example, vibration levels on a critical fan motor have exceeded a predefined threshold. This alert can be configured to automatically generate a high-priority work order in the CMMS. The work order is then dispatched to a technician with all the relevant data: the specific alert, the historical trend data, and the recommended corrective action.

This approach offers unparalleled efficiency. Instead of overhauling a gearbox every two years (the preventive approach), the team overhauls it when oil analysis shows that the lubricant viscosity has broken down and wear metals are on the rise. This "just-in-time" maintenance minimizes downtime, maximizes the useful life of components, and optimizes the allocation of maintenance resources. Platforms like MaintainNow are architected to be this central system of record, capable of integrating with these advanced monitoring tools to create a truly holistic view of asset health, bridging the gap between preventive schedules and real-time predictive insights.

Conclusion

The transition from a reactive, chaotic maintenance environment to a proactive, controlled one is one of the most impactful initiatives a facility-focused organization can undertake. It’s not merely an operational tweak; it’s a cultural transformation that pays dividends in reduced costs, enhanced safety, improved asset reliability, and higher morale. It's the difference between being a victim of your facility's circumstances and being the master of its destiny.

This transformation, however, is not sustainable through sheer force of will or by adding more staff. It requires a foundational tool that brings structure, data, and automation to the process. Modern preventive maintenance software is that tool. It eliminates the guesswork, the lost paperwork, and the dropped balls that plague manual systems. It provides a single source of truth for assets, automates the complex scheduling of maintenance planning, streamlines the execution of work orders through mobile maintenance, and builds the data-rich foundation necessary to embrace the future of predictive maintenance.

The question for today’s facility managers and operations directors is no longer *if* they should invest in a modern CMMS to power their maintenance strategy. The question is how long they can afford not to. The cost of inaction—measured in unplanned downtime, lost production, and safety risks—is a far heavier price to pay than the investment in the tools required for excellence.