Tattoo and Piercing Studios: Sterilization Equipment and Facility Compliance with CMMS

An expert's guide for tattoo and piercing studios on using a CMMS to manage sterilization equipment, ensure facility compliance, and protect client safety.

MaintainNow Team

October 12, 2025

Introduction

The front door chimes. It isn't a client. It's the health inspector, clipboard in hand, ready for a spot check. For any tattoo and piercing studio owner, this moment can trigger a cascade of anxieties. Where is the autoclave maintenance log? When was the last spore test conducted and, more importantly, where is the certificate from the lab? Is the documentation for the ultrasonic cleaner's daily function test in the right binder? This isn't just about ticking boxes on a form; it's about the fundamental trust clients place in the studio. It's about public health, professional reputation, and the very license that allows the business to operate.

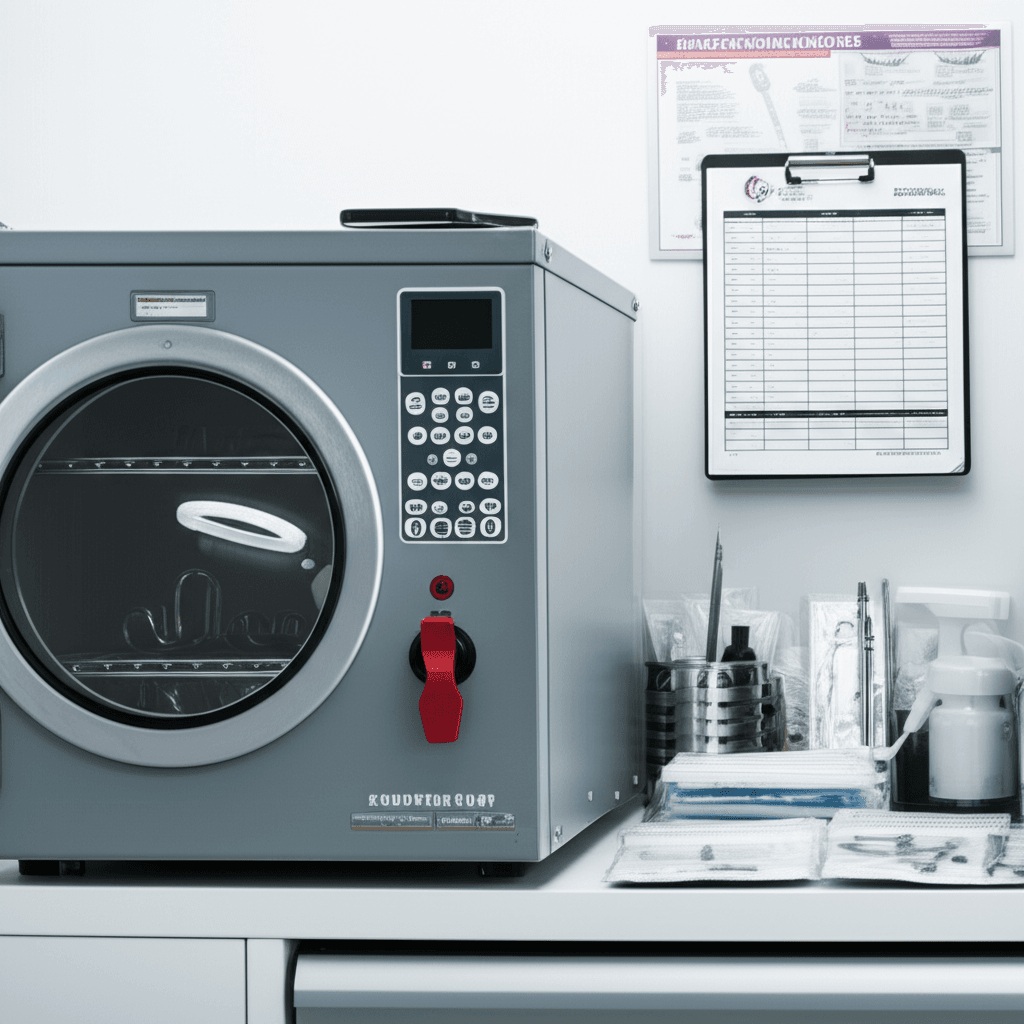

In an industry that masterfully blends artistry with a near-clinical adherence to aseptic technique, the management of critical equipment often lags behind. The same artist who can pull a perfectly straight single-needle line might be tracking the maintenance for a $5,000 Statim autoclave on a crumpled piece of paper taped to the wall. This ad-hoc approach is a significant, and unnecessary, business risk. The reality is that sterilization equipment—autoclaves, ultrasonic cleaners, and instrument washers—are the lifeblood of a safe studio. Their failure isn't an inconvenience; it's a crisis.

This is where the discipline of professional maintenance management, powered by a Computerized Maintenance Management System (CMMS), becomes not a luxury but a strategic necessity. Moving beyond binders and spreadsheets to a dedicated system isn't about adding complexity. It's about removing chaos. It's about building a robust, verifiable, and stress-free framework for compliance and operational excellence. It's about treating the back-of-house operations with the same level of professionalism and precision as the art created out front.

The High Stakes of Sterilization: More Than Just a Clean Cycle

Anyone who's been in this business for more than a few months understands that "sterilization" is a process, not just a button-push on a machine. It's a validated, documented, and repeatable series of actions that render an instrument free of all living microorganisms, including spores. The equipment that performs this critical function is complex, sensitive, and subject to failure. A run-to-failure approach is, to put it bluntly, professional malpractice.

The core assets are well-known: steam autoclaves like the workhorse Midmark M11 or the lightning-fast SciCan STATIM, and ultrasonic cleaners that perform the initial, crucial step of debris removal. Each of these pieces of equipment has a specific set of maintenance requirements dictated by the manufacturer, industry best practices, and local health department regulations. It's a lot to track. Think about the weekly, monthly, and annual needs of a typical autoclave. We're talking about daily water checks, weekly chamber cleaning with a product like Chamber Brite, monthly spore testing (biological monitoring), and annual or bi-annual preventive maintenance kits that include replacing critical seals, gaskets, and filters. Missing any one of these steps can lead to a failed cycle, or worse, a failed spore test.

A failed spore test is a catastrophic event for a studio. It immediately calls into question the sterility of every instrument processed since the last successful test. This can trigger a mandatory shutdown by the health department, a costly and reputation-damaging client notification process, and a complete re-validation of the equipment before operations can resume. This is the definition of unacceptable downtime. Every hour the autoclave is out of service is an hour of lost revenue and mounting client frustration. The financial impact of canceling a full Saturday of appointments can run into the thousands, far exceeding the cost of proper maintenance or a management system.

Beyond the immediate financial hit, there's the looming specter of regulatory compliance. OSHA's Bloodborne Pathogens Standard (29 CFR 1910.1030) implicitly requires a safe and sanitary environment, which hinges on functional sterilization equipment. Local and state health codes are even more explicit, often requiring detailed, readily accessible maintenance and testing logs. When the inspector asks to see the logbook, fumbling through a disorganized binder sends a clear message of unprofessionalism and potential risk. An organized, digital record, on the other hand, demonstrates control, diligence, and a commitment to safety protocols.

Moving Beyond the Clipboard: The CMMS Framework for Compliance

The fundamental problem with paper-based or spreadsheet-based tracking is that it's passive. It relies entirely on human memory and diligence. A CMMS is an active system. It doesn't just store information; it drives action. For a tattoo or piercing studio, this shift from passive record-keeping to active maintenance management is transformative. It creates a bulletproof system of record that satisfies regulators and ensures equipment reliability.

Preventive Maintenance: The Foundation of Reliability

The core principle of modern maintenance is shifting from reactive repairs to proactive care. This is the essence of preventive maintenance (PM). Instead of waiting for the autoclave door gasket to fail and leak steam mid-cycle, the PM program schedules its replacement every 12 months, as recommended by the manufacturer. This prevents the failure from ever happening.

A CMMS is the engine for a successful PM program. Let's walk through a real-world scenario. A studio has a Midmark M11 autoclave. The manager can create a series of recurring PM work orders within a system like MaintainNow:

* Weekly Task: "Perform Chamber Cleaning" - assigned to the head artist, with a checklist that includes using the proper cleaning solution and inspecting the gasket.

* Monthly Task: "Conduct Spore Test" - assigned to the studio manager, with instructions to place the test vial in a specific location, run a cycle, and mail it to the lab. A second step can be added to upload the lab certificate once it's received.

* Annual Task: "Annual PM Kit Replacement" - assigned to a certified technician, listing all the required parts (door gasket, dam gasket, filters) and calibration checks.

The system automatically generates these work orders on the scheduled date and notifies the assigned individual. Nothing is forgotten. The "Did we do the spore test this month?" panic is eliminated. This automation builds consistency and ensures that the manufacturer-recommended service intervals, which are crucial for warranty and liability, are met without fail. It transforms maintenance from a chore that gets pushed aside during a busy week into a non-negotiable, automated part of the studio's workflow.

Work Order Management and Auditable Records

When that health inspector arrives, their primary goal is to verify compliance. They need to see a history of care. This is where the digital work order system within a CMMS truly shines. Every single maintenance action, from a simple cleaning to a major repair, is captured in a work order.

Each digital work order becomes a permanent, unalterable record containing vital information:

* What work was performed (e.g., "Replaced door gasket and performed cycle test").

* Who performed the work.

* The date and time the work was completed.

* Any parts or materials used.

* Notes or observations ("Noticed minor mineral buildup on the heating element").

* Attached documents, like a photo of the completed work or the PDF certificate from the spore test lab.

Imagine the inspector asks for the last six months of spore test results. Instead of digging through a filing cabinet, the studio manager can pull out their phone or tablet, open the MaintainNow app (accessible via app.maintainnow.app), filter for the specific autoclave, and show a complete, time-stamped history of every spore test, complete with the attached lab certificates. The conversation shifts instantly from one of suspicion to one of professional respect. This creates an ironclad audit trail that is virtually impossible to dispute. It’s the ultimate defense against claims of negligence and the strongest proof of due diligence.

Critical Spares and Inventory Control

Effective maintenance isn't just about scheduling tasks; it's also about having the necessary parts on hand. A torn door gasket on a Friday afternoon can shut down operations for the entire weekend if a replacement isn't readily available. This is where inventory control becomes a critical component of the maintenance strategy.

A CMMS provides a simple yet powerful way to manage critical spares. Studio managers can create a digital inventory of essential items: autoclave gaskets, specific cleaning solutions, spore test kits, ultrasonic cleaner tablets, O-rings for piercing tools, and so on. For each item, they can set a minimum quantity level.

When a technician uses a door gasket to complete a PM work order, they log it against the work order. The system automatically deducts that part from the inventory count. If the count drops below the pre-set minimum, the system can automatically trigger a notification to the studio manager, telling them it's time to reorder. This eliminates stock-outs of critical components. It prevents a five-dollar part from costing hundreds or thousands of dollars in lost revenue and emergency shipping fees. This simple function ensures that the studio has what it needs, when it needs it, turning potential emergencies into routine re-stocking tasks.

Data-Driven Decisions: Using Maintenance Metrics to Improve Operations

Initially, many small business owners see a CMMS as just a scheduling tool. But its true power is unlocked when it starts to gather data. Over time, the system accumulates a rich history of every interaction with every piece of equipment. This data allows for the tracking of key maintenance metrics, providing insights that are impossible to get from a paper logbook. Even for a small studio, this data is invaluable for making smarter business decisions.

One of the most useful metrics is Total Maintenance Cost per Asset. By logging parts and labor (even if it's the owner's time, it has value) against each work order, the system can tell you exactly how much that 10-year-old ultrasonic cleaner is costing to keep running each year. Perhaps the data reveals it's breaking down every three months and the repair costs are starting to approach the price of a new, more reliable unit. This data replaces gut feelings with hard evidence, justifying capital expenditures and preventing the studio from throwing good money after bad.

Another critical metric is PM Compliance. A good CMMS will show what percentage of scheduled preventive maintenance tasks were completed on time. A PM compliance rate of 95% is a powerful testament to the studio's operational discipline and a fantastic metric to share with an inspector or even an insurance provider. It proves the studio is not just talking about safety, but actively managing it.

For studios with multiple pieces of similar equipment, Mean Time Between Failures (MTBF) becomes a relevant indicator of asset health. If two identical STATIM autoclaves were purchased at the same time, but one requires service every six months while the other runs for two years without issue, the MTBF data will clearly highlight the "problem child." This might trigger a deeper investigation into its usage, the water quality supplied to it, or whether it's simply a lemon that needs to be replaced. These are the kinds of strategic insights that elevate a studio from just being a place that does tattoos to a well-run, professional business.

Conclusion

The modern tattoo and piercing studio operates at the intersection of art, commerce, and public health. The artistry is evident on the walls and on the skin of satisfied clients. The commerce is the daily reality of running a small business. But the public health component, anchored by the uncompromising reliability of its sterilization equipment, is the foundation upon which everything else is built. To leave that foundation to chance—to rely on sticky notes, memory, and disorganized binders—is to ignore the professional standards the industry has fought so hard to establish.

Adopting a CMMS is a declaration that the operational side of the business is just as important as the artistic side. It's about systemizing safety protocols, ensuring bulletproof compliance, and minimizing the catastrophic risk of equipment downtime. It provides a framework for managing assets proactively through scheduled preventive maintenance, controlling the availability of critical parts with inventory control, and making smarter financial decisions with data-driven maintenance metrics.

This isn't an enterprise-level solution for a giant factory; systems like MaintainNow are designed to be accessible, intuitive, and mobile-first, a perfect fit for the dynamic environment of a busy studio. It puts the power of professional maintenance management into the hands of the people who need it most. The ultimate goal is peace of mind—the confidence that comes from knowing that when the health inspector walks through the door, the records are perfect, the equipment is reliable, and the studio's reputation for safety and professionalism is secure and verifiable. That is the new standard of excellence.