The Essential Guide to Compliance and Regulatory Maintenance for CMMS Professionals

Discover how compliance and regulatory maintenance enhance safety and efficiency in industrial operations. Explore strategies and CMMS solutions.

MaintainNow Team

July 21, 2025

In the world of maintenance management, one of the most critical yet often overlooked aspects is compliance and regulatory maintenance. As professionals in this field, we are tasked not only with the upkeep of equipment and assets but also with ensuring that our operations adhere to various safety protocols and regulations. This blog post dives deep into compliance maintenance, exploring its importance, challenges, and how effective maintenance planning, supported by CMMS software, can streamline the process.

Compliance maintenance is not just a legal requirement; it is a cornerstone of operational integrity. Failing to adhere to regulations can lead to hefty fines, legal repercussions, and, most importantly, safety hazards. In my experience, organizations that prioritize compliance see not only enhanced safety but also improved operational efficiency and a stronger reputation in their industry.

Understanding Compliance Maintenance

At its core, compliance maintenance involves the systematic upkeep of equipment and processes to meet regulatory standards. These regulations can span a wide array of areas, including environmental protection, workplace safety, and equipment functionality. For instance, industries like manufacturing and healthcare are governed by stringent regulations set forth by bodies like OSHA (Occupational Safety and Health Administration) or the EPA (Environmental Protection Agency).

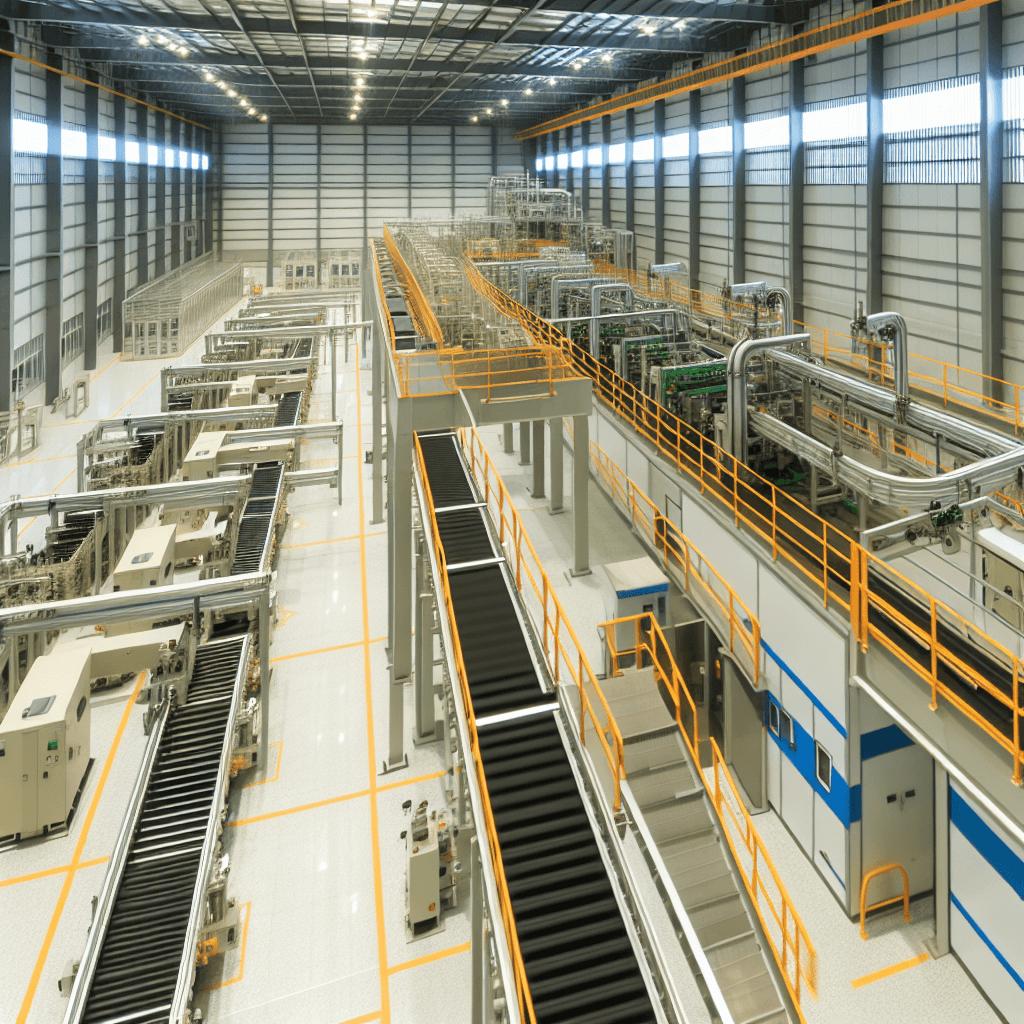

Let's consider a real-world scenario: A manufacturing facility operates heavy machinery that requires regular inspections and maintenance to comply with safety standards. The failure to conduct an annual inspection could not only result in machinery malfunction but also expose employees to hazardous conditions. By integrating compliance maintenance into their maintenance planning, this facility can mitigate risks, ensuring both employee safety and operational continuity.

The Importance of CMMS Software in Compliance Management

In today's fast-paced industrial environment, relying on manual processes for compliance management can be a recipe for disaster. This is where CMMS software, such as MaintainNow, comes into play. A robust CMMS can help automate compliance tracking, ensuring that all maintenance tasks are completed on schedule and documented properly.

Imagine having a dashboard that alerts maintenance personnel of upcoming compliance deadlines or required inspections. With MaintainNow, this is not just an idea; it’s a reality. By using such a solution, companies can streamline their maintenance activities, ensuring that nothing falls through the cracks.

Additionally, CMMS software facilitates predictive maintenance. Instead of waiting for equipment to fail and potentially violate compliance standards, predictive maintenance allows organizations to anticipate issues before they arise. This proactive approach can lead to significant cost savings and enhanced safety. For example, a facility that uses predictive analytics to monitor equipment health can replace a failing component before it leads to an accident or regulatory breach.

Navigating Challenges in Compliance Maintenance

While the benefits of compliance maintenance are clear, the challenges can be equally daunting. One of the most significant hurdles is staying updated with ever-changing regulations. Compliance requirements differ across regions and industries, making it crucial for maintenance professionals to remain vigilant.

I've seen companies struggle with compliance audits simply because they didn't have a centralized system for tracking and documenting maintenance activities. This is where a CMMS like MaintainNow shines. It provides a single source of truth for all maintenance records, making audit preparations less stressful.

Moreover, employee training plays a crucial role in ensuring compliance. Regular training sessions on safety protocols and regulatory requirements can empower employees to take ownership of their roles. By integrating training modules into your CMMS, you can ensure that employees have access to the latest compliance information and best practices.

Best Practices for Implementing Compliance Maintenance

To successfully implement compliance maintenance within your organization, consider the following best practices:

- 1. Develop a Compliance Checklist: Create a detailed checklist of all regulatory requirements relevant to your operations. This will serve as a foundation for your compliance maintenance planning.

- 2. Utilize CMMS Features: Leverage the full capabilities of your CMMS software. Use it for scheduling maintenance tasks, tracking compliance deadlines, and documenting completed work.

- 3. Conduct Regular Audits: Schedule periodic audits to evaluate your compliance status. This proactive approach will help identify potential gaps and areas for improvement.

- 4. Foster a Culture of Safety: Encourage employees to prioritize safety and compliance. This can be achieved through ongoing training and open communication about compliance protocols.

- 5. Collaborate with Experts: Don’t hesitate to consult with compliance experts or legal advisors to ensure that your maintenance strategies align with current regulations.

- 6. Monitor and Adapt: Compliance regulations are not static. Regularly review and adapt your maintenance practices to align with new laws or standards.

Real-World Applications of Compliance Maintenance

To illustrate the practical applications of compliance maintenance, let’s look at a case study from the food processing industry. A company faced significant challenges in maintaining compliance with food safety regulations. Their existing processes were manual and fragmented, leading to lapses in compliance checks.

Upon implementing MaintainNow, they were able to digitize their compliance processes. The software allowed them to schedule regular inspections, track maintenance history, and generate reports for compliance audits. Within six months, the company not only passed their next regulatory audit with flying colors but also reduced their maintenance costs by implementing a predictive maintenance strategy.

This real-world example highlights the transformative impact that a well-implemented compliance maintenance program can have on an organization. It underscores the importance of using technology like CMMS to facilitate compliance and improve overall operational efficiency.

Conclusion

As maintenance professionals, we have a significant responsibility to ensure that our operations comply with regulatory standards while maintaining safety and efficiency. Compliance and regulatory maintenance is not merely a box to check; it is an essential component of a successful maintenance management strategy.

By leveraging CMMS software like MaintainNow, we can streamline compliance processes, enhance safety protocols, and reduce operational risks. Remember, the goal is not just to meet compliance requirements but to foster a culture of safety and excellence in our organizations.

In the ever-evolving landscape of regulations, staying informed and proactive is key. By implementing the strategies and best practices discussed in this post, you will be better equipped to navigate the complexities of compliance maintenance. So, let’s embrace the challenge and ensure our operations are not only compliant but also leading the way in safety and efficiency.