The Hidden Cost of Reactive Maintenance: Why Executives Are Moving to Preventive & Predictive Strategies

An industry expert analysis of the true, hidden costs of run-to-failure maintenance and why a strategic shift to preventive and predictive models is critical for operational success.

MaintainNow Team

February 14, 2026

Introduction

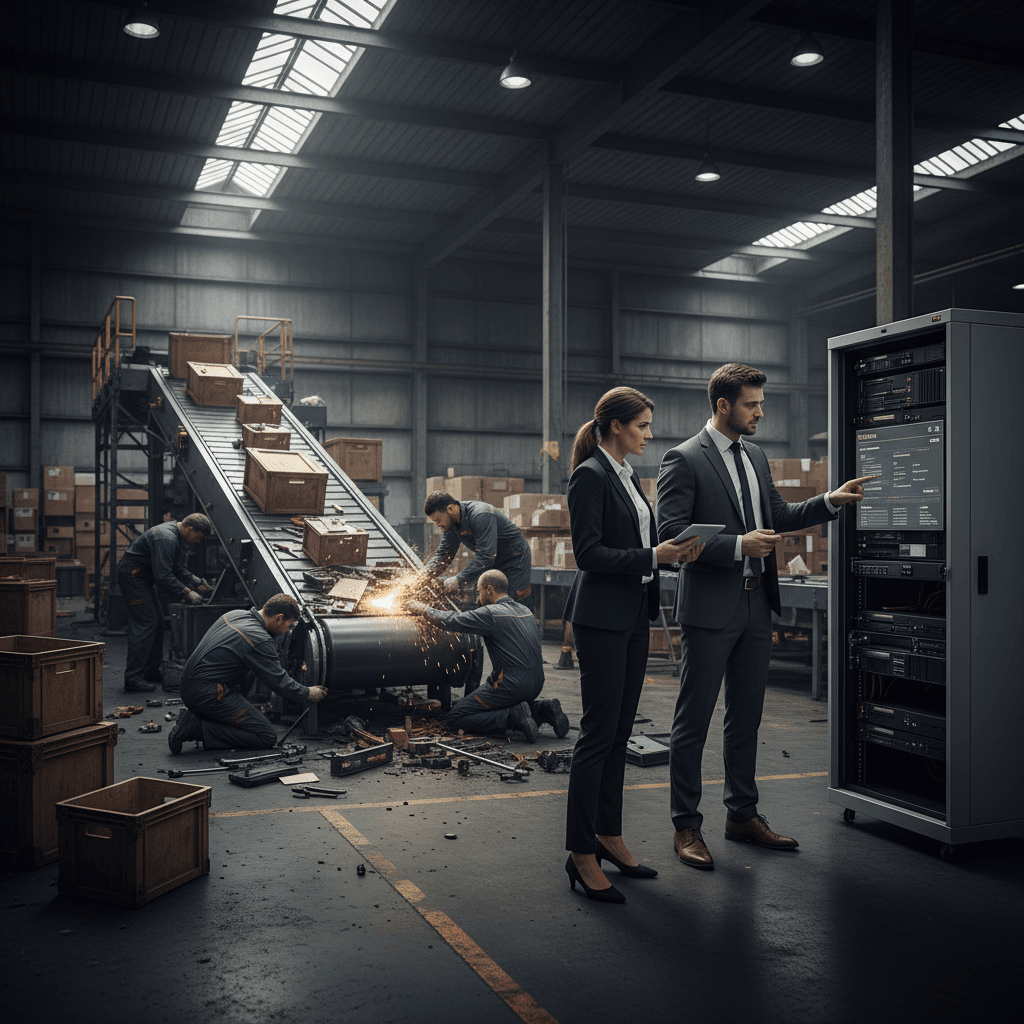

It's 3:00 PM on a Friday in July. The call comes in. The main chiller for Building B, the one that serves the data center and the executive suites, has gone down. Not just a minor fault, but a catastrophic compressor failure. The operations team scrambles. Technicians are pulled from other jobs. Frantic calls are made to suppliers, begging for emergency parts at a premium. Overtime pay kicks in. Meanwhile, servers are overheating, and the CEO's office is quickly becoming a sauna.

This scenario isn't hypothetical. For too many facility managers and maintenance directors, it's a recurring nightmare. This is the reality of reactive maintenance, often called the "run-to-failure" model. It’s a strategy born not of choice, but of necessity, insufficient resources, or a lack of visibility into asset health. It feels like constant firefighting because, well, it is.

For decades, the direct costs of these failures—the overtime labor, the rush shipping on spare parts, the replacement component itself—were seen as a standard cost of doing business. But a fundamental shift is happening in boardrooms and on plant floors. Executives and operations leaders are starting to see the iceberg. They're realizing that the invoice for the emergency repair is just the tip. The real, debilitating costs are hidden below the surface, silently eroding profitability, productivity, and safety.

The conversation is no longer about simply fixing what's broken. It's about fundamentally re-engineering the maintenance management philosophy from a reactive, cost-center mindset to a proactive, value-creation engine. It's about moving from firefighting to fire prevention, powered by data, strategy, and modern tools.

The Iceberg of Reactive Maintenance: Deconstructing the True Cost

When a critical asset fails, the immediate financial hit is obvious. The work order is generated, parts are ordered, labor is allocated. But these visible expenses are dwarfed by a cascade of indirect and opportunity costs that ripple through the entire organization. Understanding these hidden costs is the first step toward building a business case for change.

The Obvious Costs: Tip of the Iceberg

These are the numbers that show up clearly on a balance sheet. A maintenance manager can point directly to them.

* Emergency Labor: Technicians are paid overtime, often at time-and-a-half or double-time rates. If specialized contractors are needed on short notice, their emergency call-out fees can be astronomical. A standard HVAC contractor might charge double for a weekend call.

* Expedited Parts & Shipping: A VFD that costs $5,000 with standard shipping can suddenly cost $7,500 when you need it flown in overnight. Sourcing spare parts under duress always means paying a premium. There's no time to shop for better pricing.

* Equipment Replacement: Often, a run-to-failure approach doesn't just damage one component. A seized bearing can destroy a motor shaft, turning a $200 repair into a $10,000 motor replacement. The failure cascades, and the eventual repair is far more extensive and expensive than the initial problem.

But this is where most legacy accounting for maintenance stops. And it's a dangerously incomplete picture.

The Hidden Costs: What Lies Beneath

Here, the financial impact becomes harder to quantify but is exponentially larger. This is what keeps experienced facility directors up at night.

Operational Downtime: This is the single biggest hidden cost. Downtime is never just idle equipment; it’s a complete halt of value creation. The impact varies by industry, but it's always significant.

* In a manufacturing plant, a failed conveyor belt can bring an entire production line to a standstill. If that line generates $50,000 in revenue per hour, a four-hour outage is a $200,000 loss, not including the cost of the belt.

* In a commercial office building, a failed HVAC system leads to tenant complaints, potential lease violations, and damage to the building's reputation.

* In a hospital, a failed backup generator or medical air compressor isn't a financial problem—it's a patient safety crisis. The liability is immeasurable.

* In a distribution center, a broken sorter or dock leveler can delay hundreds of shipments, triggering penalties with major clients and damaging supply chain relationships.

Reduced Asset Lifespan: Running equipment to failure is like driving a car without ever changing the oil. Sure, it runs for a while, but you're guaranteeing a shorter, more problematic life. A well-maintained air handler might last 20-25 years. One that is constantly run-to-failure might need a full replacement in 15 years. That's a massive capital expenditure pulled forward by five to ten years, all because of a flawed maintenance strategy. The cumulative effect across an entire portfolio of assets is a staggering financial burden.

Safety & Compliance Risks: Catastrophic failures are inherently dangerous. A bursting hydraulic line can cause serious injury. An electrical fault can lead to fire. Beyond the immediate human cost, these incidents trigger OSHA investigations, fines, and massive increases in insurance premiums. The reactive "fix-it-when-it-breaks" model is a documented liability. It creates an environment where technicians are often forced to make repairs under immense pressure, in hazardous conditions, increasing the risk of accidents.

Wasted Labor & Inefficiency: In a reactive environment, technician "wrench time"—the actual time spent performing hands-on maintenance—is shockingly low. Industry data often shows it can be as low as 25-35%. The rest of the time is spent diagnosing the problem under pressure, hunting for information, tracking down the right spare parts, and filling out paperwork after the fact. It’s a deeply inefficient use of a skilled, and expensive, workforce. Technicians become professional firefighters, running from one emergency to the next, with no time for the value-added work that prevents future fires.

This chaotic cycle leads to low morale, burnout, and high turnover among the very people organizations rely on to keep things running.

The Proactive Paradigm: Shifting from Firefighting to Strategic Management

Recognizing the crippling cost of reactivity is one thing. Escaping it is another. The solution lies in a strategic pivot to proactive maintenance methodologies: Preventive Maintenance (PM) and Predictive Maintenance (PdM). This isn't just about scheduling tasks; it's about a cultural and operational transformation, enabled by modern CMMS software.

The Foundation: Preventive Maintenance (PM)

Preventive maintenance is the bedrock of any stable maintenance program. The concept is simple: perform maintenance tasks on a predetermined schedule (time-based, like inspecting a fire extinguisher every year, or usage-based, like changing the oil in a generator every 250 run-hours) to reduce the likelihood of failure.

It’s about replacing a fan belt *before* it snaps. It's about lubricating bearings *before* they seize. It's about cleaning condenser coils *before* they cause a compressor to overheat and fail.

The challenge? Scale. A small facility might have a few dozen assets to track. A corporate campus, hospital, or manufacturing plant can have thousands. Managing this with spreadsheets, whiteboards, or (worse) institutional memory is impossible. PMs get missed. Records are lost. The system collapses back into reactivity.

This is where a dedicated CMMS software platform becomes non-negotiable. A modern system, like the one offered by MaintainNow, acts as the central brain for the entire PM program. It houses all asset data, defines PM tasks and schedules, and automatically generates work orders for technicians. When a work order for "Quarterly HVAC Filter Change - AHU-04" is due, the system assigns it to the right technician, complete with checklists, safety procedures, and a record of the asset’s history. The technician can then close out the work on a mobile device right at the asset, creating a perfect, auditable record.

This level of organization transforms the maintenance department from a chaotic emergency room into a well-run clinic focused on wellness and prevention.

The Next Frontier: Predictive Maintenance (PdM)

If PM is about performing maintenance on a schedule, PdM is about performing it at the exact right moment. It uses condition-monitoring technology to "listen" to equipment and detect the earliest signs of a potential failure. It's data-driven, precise, and incredibly efficient.

Think of it this way: a PM program might dictate changing the bearings on a critical motor every two years. But what if vibration analysis shows those bearings are still in perfect condition? Replacing them is a waste of parts, labor, and downtime. Conversely, what if the analysis shows a bearing starting to degrade after just one year? Waiting another year based on the PM schedule would be inviting a catastrophic failure.

PdM technologies are more accessible than ever:

* Vibration Analysis: Detects imbalances, misalignments, and bearing wear in rotating equipment like pumps, fans, and motors.

* Thermal Imaging: Uses infrared cameras to spot "hot spots" in electrical panels, transformers, and mechanical systems—often a precursor to failure.

* Oil Analysis: Analyzes lubricant for contaminants or metal particles that indicate internal wear on gearboxes, engines, and hydraulic systems.

* Ultrasonic Analysis: Listens for high-frequency sounds that can indicate gas leaks, electrical arcing, or early-stage bearing faults.

A sophisticated maintenance management strategy often blends PM and PdM. PMs cover the basics for most assets, while PdM is applied to the most critical or failure-prone equipment. The data from these PdM tools can then be fed into a CMMS, triggering a work order when a certain threshold is breached. For example, when vibration on Pump-101 exceeds a predefined limit, a work order is automatically generated to inspect it. This is the peak of proactive management—solving a problem before it's even a problem.

Building the Business Case: The Tangible ROI of Proactive Maintenance

The shift from reactive to proactive requires an investment—in software, in training, and potentially in condition-monitoring tools. To get executive buy-in, maintenance leaders must frame this not as a cost, but as one of the highest-return investments the organization can make.

Hard Numbers: Cost Reduction and Asset Longevity

The data is clear. According to industry studies, a well-implemented proactive maintenance program can:

* Reduce overall maintenance costs by 15% to 30%. This comes from eliminating overtime, reducing the need for expensive emergency repairs, and optimizing the use of spare parts inventory.

* Extend equipment lifespan by 20% or more. This has a profound impact on capital expenditure (CapEx) budgets. Deferring the multi-million dollar replacement of a chiller, a roof, or a fleet of production machines for several years is a massive win for the organization's bottom line.

* Reduce equipment downtime by 35% to 75%. The financial impact of this, as discussed, is enormous. More uptime means more production, happier tenants, and a more resilient operation.

These aren't abstract figures. They are achievable results. The key is having a system to manage the process. A CMMS provides the framework for achieving these numbers by ensuring PMs are completed on time, every time, and that all work is tracked.

The Power of Data: From Guesswork to Insight

A reactive maintenance world is data-poor. A proactive world, powered by a CMMS, is data-rich. Every work order, every PM task, every part used is a data point. Over time, this data becomes an invaluable strategic asset.

A robust asset tracking module within a CMMS like MaintainNow (accessible via their main site https://maintainnow.app and technician-facing app at https://www.app.maintainnow.app/) provides a complete picture. Facility managers can instantly see:

* Costliest Assets: Which pieces of equipment are consuming the most labor hours and parts? This helps prioritize replacement or refurbishment decisions.

* Failure Trends: Is a certain model of pump failing more often than others? This data can inform future purchasing specifications.

* Technician Productivity: Where is the team's time being spent? This allows for better resource allocation and identifies training needs.

* Inventory Optimization: Which spare parts are used most frequently? This prevents overstocking of unnecessary items and stock-outs of critical ones.

Without a centralized system, this information is trapped in paper files, disparate spreadsheets, or the heads of senior technicians. A CMMS unlocks it, turning raw data into actionable intelligence that drives smarter budgeting, staffing, and capital planning. It allows a maintenance director to walk into a budget meeting with a dashboard full of hard data, not just anecdotes.

De-Risking the Operation: Compliance and Standardization

In many sectors—healthcare, pharmaceuticals, aviation, food and beverage—maintenance isn't just about uptime; it's about compliance. Audits from bodies like The Joint Commission, FDA, or FAA require meticulous documentation. Proving that life safety equipment was inspected on schedule isn't optional.

A CMMS provides an unshakeable, auditable trail. Every action is time-stamped and associated with a specific asset and technician. A manager can pull a complete maintenance history for any asset in seconds. This dramatically simplifies audit preparation and mitigates the significant financial and reputational risk of non-compliance.

Furthermore, a CMMS standardizes work. Checklists and standard operating procedures (SOPs) can be attached to work orders, ensuring that every technician performs a task the same way, to the same high standard. This is critical for quality control, safety, and training new team members.

Conclusion

Let's return to that 3:00 PM Friday failure. In a proactively managed facility, the story would be different. Six weeks earlier, a routine vibration analysis on the chiller motor, scheduled and tracked by the CMMS, detected a slight increase in bearing noise. A work order was automatically generated. A technician investigated, confirmed the early-stage fault, and scheduled a planned replacement of the bearings for the following week during a scheduled low-demand period overnight.

The parts were ordered with standard shipping. The repair was done on straight time. There was zero operational downtime. The catastrophic failure never happened. The crisis was averted, not through heroic firefighting, but through quiet, data-driven competence.

The transition from a reactive to a proactive maintenance culture is not merely about implementing a new piece of software. It is a strategic imperative for any organization that relies on physical assets to generate value. The hidden costs of the run-to-failure model—the lost production, the safety risks, the shortened asset life, the constant chaos—are no longer acceptable costs of doing business. They are symptoms of an outdated operational philosophy.

Investing in a modern maintenance management strategy, underpinned by a powerful and user-friendly CMMS software platform, is the most direct path to operational stability, efficiency, and profitability. The cost of inaction, of remaining trapped in the cycle of firefighting, is a price that modern, competitive organizations can no longer afford to pay. The question for executives and facility leaders is no longer *if* they should make the shift, but how quickly they can get there.