The Parts Cage Paradox: Why Your MRO Inventory is Costing More Than You Think

A deep dive into MRO inventory management, exposing the hidden costs that erode maintenance budgets and how a modern CMMS transforms your parts cage into a strategic asset.

MaintainNow Team

October 10, 2025

Anyone who's managed a maintenance team for more than a week knows the feeling. The call comes in, a critical asset is down. A seasoned technician diagnoses the problem in minutes—a failed bearing on a primary conveyor motor. She heads to the parts crib with the confidence of a surgeon reaching for a familiar instrument. And then... the shelf is empty. The CMMS said there were two in stock. The logbook shows one was checked out last month, but the other has simply vanished. Now, what should have been a 30-minute fix becomes an hours-long, or even days-long, fire drill involving frantic calls to suppliers, exorbitant rush shipping fees, and a production line bleeding money with every tick of the clock.

This isn't a rare occurrence; it's a daily reality in thousands of facilities. This is the Parts Cage Paradox. Organizations invest millions in equipment, technology, and skilled labor, only to have their entire operation held hostage by a disorganized, untracked, and fundamentally broken approach to MRO (Maintenance, Repair, and Operations) inventory. It's often seen as a secondary, administrative task—a necessary evil managed on a spreadsheet or, worse, by tribal knowledge. But this perspective is dangerously flawed. MRO inventory management isn't a support function of maintenance. It is the fuel for the engine. Without it, the most sophisticated maintenance strategy in the world grinds to a halt. The truth is, your inventory, or lack thereof, is quietly dictating the success or failure of your entire maintenance program, directly impacting your most critical maintenance metrics and draining your budget in ways you might not even be tracking.

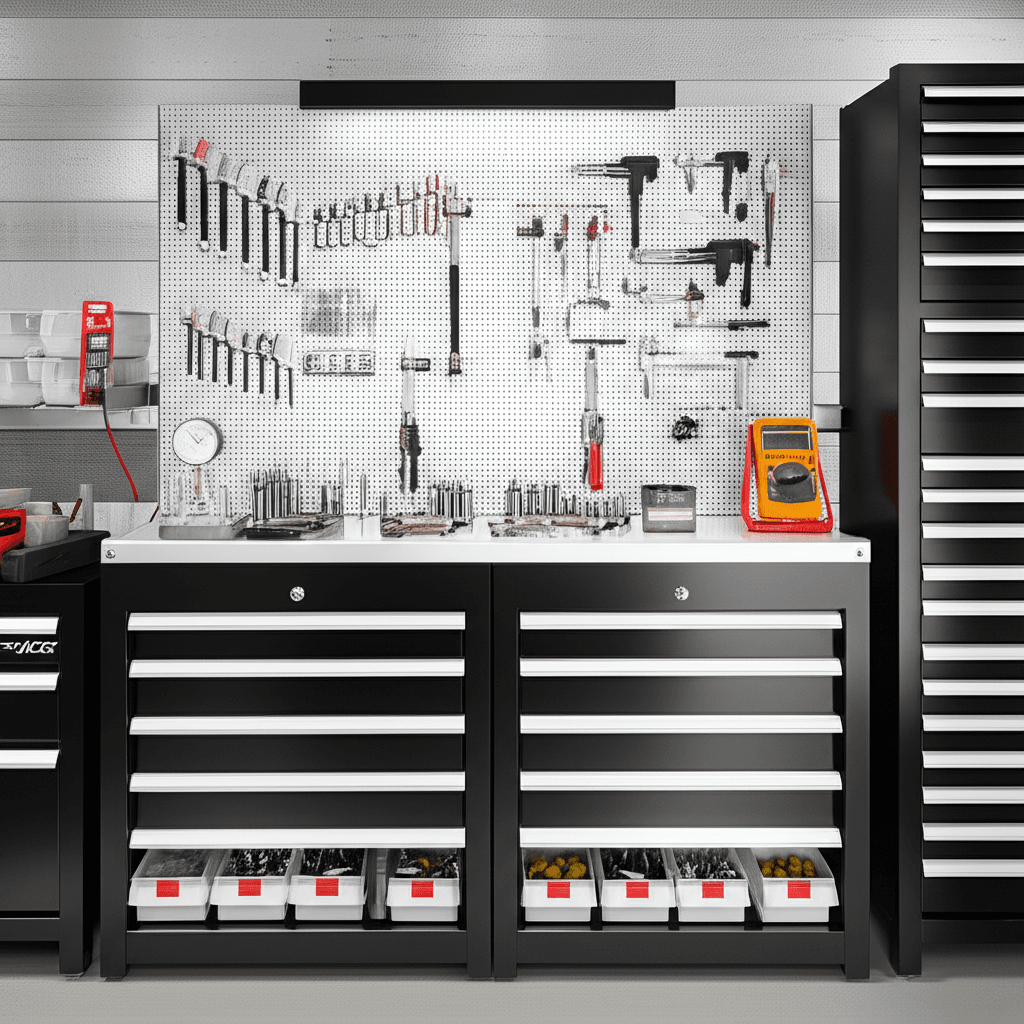

The problem runs deeper than just stockouts. It’s a complex web of inefficiencies that spiderwebs out to affect every corner of the operation. It’s the technician's "walk of shame" back from an empty parts bin. It's the "squirrel stash" of critical parts hoarded in a senior tech’s locker because he doesn’t trust the system, representing thousands in tied-up capital and ghost assets that don't officially exist. It’s the slow, creeping death of obsolescence, where a part for a decommissioned asset sits on a shelf for a decade, gathering dust until it's finally written off. These are not just anecdotes; they are symptoms of a systemic failure to treat inventory as the strategic asset it truly is. Getting a handle on this isn’t just about tidying up the storeroom. It’s about fundamentally re-engineering the flow of work, information, and materials within your maintenance department.

The Hidden Costs of a Disorganized Storeroom

When finance departments look at MRO inventory, they typically see one number: the dollar value of the parts on the shelves. But seasoned facility managers know that’s just the tip of the iceberg. The true cost of a poorly managed storeroom is a beast of a different nature, composed of insidious expenses that rarely show up as a line item on a budget report but are devastatingly real.

First, there are the carrying costs. Industry estimates often place the annual cost of holding inventory at 20-30% of its value. This isn't just the cost of the physical space, the shelving, the lighting, and the climate control. It includes the cost of capital tied up in those parts—money that could be invested elsewhere. It includes insurance. It includes the labor required to manage the storeroom, to do periodic counts, to receive and put away stock. And, most significantly, it includes the cost of shrinkage and obsolescence. That specialized control board for a 20-year-old Siemens PLC that you paid a premium for five years ago? It's worthless if that machine has since been replaced. A disorganized system makes it nearly impossible to track and manage the lifecycle of your spares, leading to a storeroom that is part museum, part landfill.

But the carrying costs, as significant as they are, often pale in comparison to the impact on labor productivity. Think about the technician's day. The most valuable part of their time is "wrench time"—the time they are actively performing maintenance tasks on an asset. Everything else is a form of waste. When a technician has to walk from a rooftop AHU unit down three floors to the parts crib, search for a part, find it's not there, consult a manual, talk to a supervisor, and then try to source it externally, how much wrench time do they get in that hour? Maybe ten minutes. The rest is wasted motion. This is a direct, catastrophic blow to your labor efficiency KPIs. We've seen maintenance teams where technicians spend upwards of 25% of their day just on parts-related logistics. Imagine reclaiming even half of that time. It's like adding another technician to your team for every four you have on staff, without the added payroll. A modern CMMS, especially one with a fluid mobile interface like the one found at app.maintainnow.app, allows a tech to verify parts availability from their phone before they even leave the asset, turning a 30-minute gamble into a 30-second verification.

Then there's the ultimate cost: extended asset downtime. This is where the numbers get truly frightening. That missing $50 bearing doesn't cost $50. It costs the thousands, or even tens of thousands, of dollars in lost production for every hour that conveyor is down. It costs the overtime pay for the technicians who have to stay late. It costs the trust of the operations team, who now see maintenance as unreliable. This is the real, tangible impact of poor inventory control. A proper maintenance strategy is about controlling asset availability, and you cannot control availability if you don't control the parts needed to maintain the asset. A run-to-failure approach might seem cheap on paper, but when the failure happens and the part isn't on hand, the costs spiral out of control. Even a well-planned preventive maintenance program falls apart if the filters, belts, and lubricants specified for the job aren't kitted and ready when the work order is issued.

The ripple effects are everywhere. Inaccurate inventory data leads to poor purchasing decisions. You either overbuy, tying up capital and creating the obsolescence problem, or you underbuy, leading to the stockouts and downtime. It creates a culture of distrust, where technicians hoard parts because they can't rely on the official system, which only makes the official system's data even more inaccurate—a vicious cycle. Breaking this cycle requires a fundamental shift in thinking and, more importantly, the right tools to enforce a new reality.

From Reactive Chaos to Strategic Control: The CMMS Linchpin

The journey from a chaotic, reactive storeroom to a strategic, well-oiled MRO inventory system is impossible without a central nervous system. For decades, maintenance departments have tried to manage this with paper logs, Excel spreadsheets, or standalone inventory programs that don't talk to anything else. These are all digital bandaids on a fundamentally analog problem. They track what's on the shelf (often inaccurately) but fail to connect inventory to the two things that matter most: the work being done and the assets being maintained.

This is where a true maintenance management software platform becomes the linchpin. A modern CMMS doesn't just hold a list of parts. It creates an interconnected ecosystem where inventory is an active participant in the entire maintenance workflow. The moment a work order is generated, the system should be able to identify the asset, cross-reference its bill of materials (BOM), and automatically reserve the necessary parts. When a technician is assigned a preventive maintenance task for a Trane chiller, the work order should come with a pre-populated parts list: two oil filters, three belts of a specific size, and a canister of refrigerant. This isn't just convenient; it transforms the entire process.

The power of this integration is what separates basic systems from enterprise-level asset management solutions. Think about min/max levels. In a spreadsheet, setting a minimum stock level for a part is just a guess. In a CMMS like MaintainNow, that level can be intelligently calculated based on historical consumption data, supplier lead times, and the criticality of the assets that use that part. When stock of a critical motor starter drops below the minimum threshold because a technician logged its use against a work order on their mobile device, the system can automatically generate a purchase requisition for the procurement team. This closes the loop. It moves the process from a person remembering to check a shelf to a system ensuring that parts are replenished based on actual, real-time usage. This single function is the foundation of moving from a reactive to a proactive maintenance strategy.

Furthermore, by linking every part consumed directly to a work order and, by extension, to a specific asset, the CMMS begins to build an incredibly rich data history. Over time, facility managers can see not just that they used 50 bearings last year, but exactly which machines used them. If one particular air handler is chewing through belts at three times the rate of its identical counterparts, that's a massive red flag. It points to a deeper issue—misalignment, a failing motor, an engineering flaw—that would be completely invisible in a disconnected system. This data transforms the maintenance team from parts-changers to asset performance managers. It provides the hard evidence needed to justify a replacement or overhaul, turning maintenance management from a cost center into a value-driver. Organizations using integrated platforms like MaintainNow discover they can finally calculate the true total cost of ownership for their critical assets, a KPI that is pure gold when it comes to capital planning and budget defense.

The CMMS becomes the single source of truth. No more conflicting spreadsheets. No more questioning whether the data is accurate. When the system is used properly, from procurement to receiving to consumption on the floor, it provides a transparent, auditable trail for every single component in the storeroom. This level of control and visibility is simply not achievable with manual or disjointed systems. It’s the foundational requirement for any serious attempt at maintenance optimization.

Advanced Tactics: Optimizing Inventory for Modern Maintenance

Once a solid CMMS foundation is in place, with accurate data flowing from the shop floor, the door opens to a whole new level of strategic inventory optimization. This is where a maintenance department can truly start to flex its muscles, using data not just to keep parts on the shelf, but to actively reduce costs, improve wrench time, and support more advanced maintenance strategies.

One of the most impactful of these tactics is kitting. The concept is simple, but the effect on efficiency is profound. Instead of a technician receiving a work order and then going on a "scavenger hunt" around the storeroom for the seven or eight different parts they need, the parts are pre-assembled into a single kit. When the PM for "AHU-04 Quarterly Service" is scheduled, the system flags the need for "Kit-AHU-04-QTRLY." A storeroom attendant can then pick the two filters, one belt, and packet of lubricant, bundle them together, and have them ready for the technician. This can slash the non-wrench time portion of a job by 50% or more. The technician grabs one kit and goes. It standardizes the job, reduces the chance of forgetting a part, and keeps your most expensive resource—your skilled technician—focused on their primary task. This is a classic lean manufacturing principle applied to maintenance, and a good CMMS is what makes it scalable and manageable.

Another powerful data-driven approach is ABC analysis. This is the application of the Pareto principle to inventory: not all parts are created equal. In any given storeroom, a small percentage of items (the 'A' items) will typically account for a large percentage of the annual spend. Another group (the 'C' items) will comprise a huge number of SKUs but represent a tiny fraction of the cost—think nuts, bolts, and common fittings. The 'B' items are everything in between. It makes no sense to apply the same level of control to a $5 washer as you do to a $5,000 variable frequency drive. A CMMS that tracks usage and cost data makes it easy to classify your inventory this way. You can then focus your tightest controls, like regular cycle counting and careful supplier management, on the 'A' items where the financial risk is highest. For 'C' items, you can use simpler methods like a two-bin system or allow for higher safety stock levels, because the cost of carrying them is far less than the cost of a technician's time spent looking for one. This strategic allocation of effort is a hallmark of a mature maintenance organization.

Perhaps the most exciting frontier is the link between inventory management and the rise of predictive maintenance (PdM). A PdM strategy relies on condition-monitoring sensors—vibration analysis, thermography, oil analysis—to predict when a component is going to fail. This is the future, a way to eliminate unplanned downtime almost entirely. But a prediction is useless without a plan of action. What happens when a sensor on a critical exhaust fan indicates a bearing is likely to fail within the next 72 hours? An advanced, integrated system doesn't just send an alert. It communicates with the CMMS. The MaintainNow platform, for example, can be configured to automatically check MRO inventory for the required bearing and a seal kit. If the parts are in stock, it reserves them and generates a high-priority work order for a planned replacement on the next available maintenance window. If the part is not in stock, it can trigger an expedited purchase order. This closes the loop between high-tech prediction and on-the-ground execution. Your inventory system becomes a critical enabler of your most advanced maintenance strategy, ensuring that the promise of predictive maintenance can actually be delivered. Without this tight integration, PdM is just an expensive alarm clock.

The Human Element: Gaining Buy-In and Driving Adoption

The most sophisticated CMMS in the world is destined to fail if the people on the floor don't use it consistently and correctly. The biggest hurdle in any maintenance technology implementation isn't the software; it's the culture. It's overcoming the "we've always done it this way" mentality and convincing a team of busy, often skeptical, technicians that this new process is going to make their lives easier, not harder.

Success hinges on a few key factors. First, the system has to be incredibly easy to use, especially at the point of execution. Clunky, desktop-bound interfaces don't work for technicians who are on the move. They need a simple, intuitive mobile application that works as well in a boiler room with poor connectivity as it does in the office. The process of scanning a barcode to check out a part, or logging consumption against a work order, needs to be faster and easier than the old way of scribbling on a notepad. When a tech can pull up a digital schematic and the complete parts list for an asset on their phone (a core capability of systems found at app.maintainnow.app), they begin to see the tool as an asset, not a burden.

Second, the "why" must be communicated clearly and often. Technicians need to understand that tracking parts usage isn't about micromanagement. It's about ensuring that the next time they need a critical part, it will actually be there. It's about eliminating the frustrating search for parts so they can focus on the skilled diagnostic and repair work they were hired to do. Frame it as a tool to increase wrench time and reduce headaches. When they see that the data they are inputting leads to better-planned work, pre-kitted jobs, and fewer stockouts, they become champions of the system.

Finally, there must be a commitment to process and data integrity from the top down. This means establishing clear procedures for everything: how parts are received, how they are issued, how returns are handled, and how cycle counts are performed. And it means holding people accountable for following those procedures. A CMMS is a powerful tool, but it's not magic. It relies on a steady stream of accurate data. If parts are leaving the storeroom without being logged against a work order, the system's inventory count will drift, and trust in the system will erode. Leadership must champion the process, provide the necessary training, and use the KPIs and reports generated by the system to make decisions. When the team sees that management is using the data to justify budget increases, invest in better tools, and plan work more effectively, they understand that their contribution at the ground level has a real, positive impact on the entire operation.

Inventory management is not just about counting widgets. It is the bedrock of operational readiness. It is the critical link between a planned maintenance strategy and flawless execution. Getting it right doesn't just save a few dollars on parts; it unlocks hidden capacity in your team, dramatically improves asset reliability, and transforms the maintenance department from a reactive fire brigade into a strategic partner in the success of the entire enterprise. The journey starts with recognizing the true, hidden costs of the status quo and understanding that the path forward lies in a single, integrated system of record—a platform like MaintainNow that connects your people, your assets, and the parts that keep them running.