Why Your Manufacturing Team Needs CMMS: Reducing Downtime and Maximizing OEE

A seasoned expert's take on how CMMS software transforms manufacturing maintenance, slashes costly downtime, and drives OEE by optimizing assets and workflows.

MaintainNow Team

October 12, 2025

Introduction

It’s a sound every plant manager, maintenance director, and operator dreads: the sudden, jarring silence when a critical production line grinds to a halt. That silence is never just silence. It's the sound of money being lost. It’s the ticking clock of customer deadlines being missed. It’s the prelude to a frantic scramble—phone calls, two-way radios crackling, and technicians rushing to diagnose a problem with incomplete information and a mountain of pressure on their shoulders.

For decades, many manufacturing facilities have run on a cocktail of tribal knowledge, well-worn spreadsheets, and a heroic (but unsustainable) "firefighting" maintenance culture. The whiteboard in the maintenance shop is a collage of grease-stained notes, the filing cabinet is overflowing with unorganized work order history, and the true cost of a breakdown is anyone’s guess. This is the reality of reactive maintenance. And in today’s hyper-competitive market, it’s a recipe for falling behind.

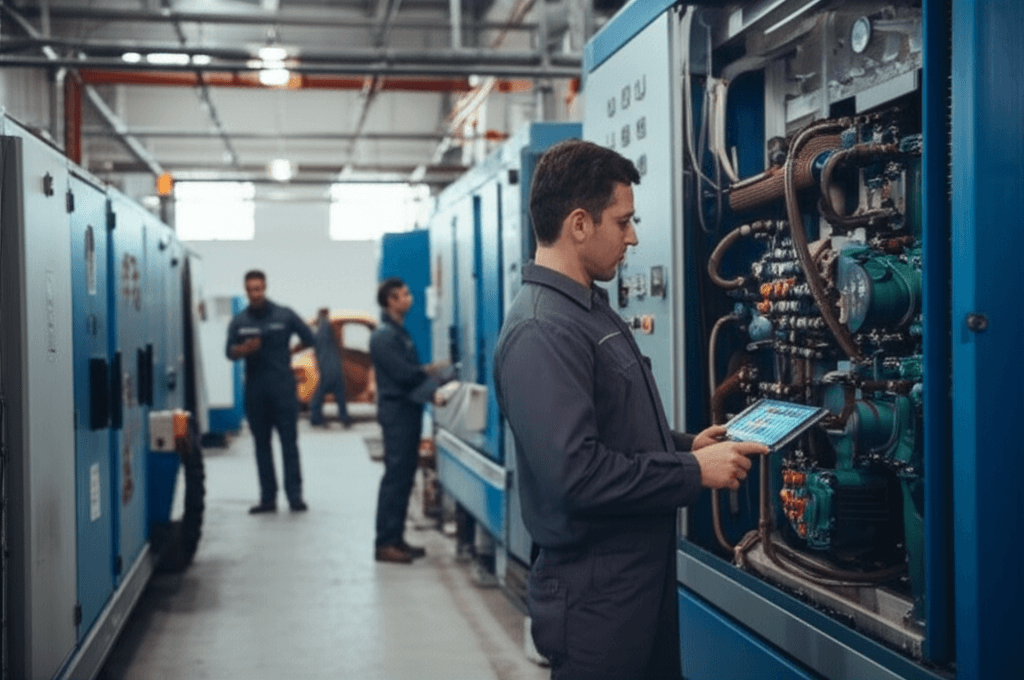

The strategic shift from this chaotic, reactive state to a controlled, proactive operation is the single most impactful change a manufacturing facility can make to its bottom line. This transformation doesn't happen by magic or by simply asking people to work harder. It requires a system. A central nervous system for your maintenance operations. This is the role of a modern Computerized Maintenance Management System, or CMMS software.

Thinking of a CMMS as just another piece of software is a fundamental misunderstanding. It’s a strategic tool, a data-driven framework for decision-making that directly targets the holy grail of manufacturing metrics: Overall Equipment Effectiveness (OEE). OEE is the ultimate measure of your plant's productivity, and at its core, it's profoundly influenced by the reliability and performance of your assets. In other words, it's all about maintenance.

The High Cost of the Status Quo: Why Spreadsheets and Clipboards Fail in Modern Manufacturing

Before looking forward, it's critical to take an honest look at the current state of operations in facilities that haven't adopted a centralized maintenance system. The problems are often so ingrained in the daily routine that they become accepted as "the cost of doing business." They are anything but. These inefficiencies are a constant drain on resources, morale, and profitability.

The Vicious Cycle of Reactive Maintenance

The "run-to-failure" model is the default mode for many. An asset runs until it breaks, and only then does it get attention. On the surface, it can feel like it’s saving money—why fix what isn't broken? But the true costs are staggering and often hidden. Unplanned downtime is exponentially more expensive than planned downtime. A planned shutdown for a 30-minute PM can be scheduled during a changeover. An unplanned breakdown of the same component can take down a line for four hours during peak production, scrapping work-in-progress and causing a cascade of delays downstream.

This constant firefighting creates a vicious cycle. Technicians are so busy putting out fires that they have no time for the preventive tasks that would have stopped the fires from starting in the first place. The backlog of PMs grows, leading to more breakdowns, which in turn consumes all available labor, further neglecting preventive work. It’s a downward spiral. This environment also burns out your most skilled technicians. Their days are filled with high-stress, emergency repairs instead of value-added work like root cause analysis or system improvements. They become experts at patching things up, not at making them better, and that deep-seated institutional knowledge eventually walks out the door upon retirement.

Data Silos and the Lack of Visibility

How can a maintenance manager make a strategic decision about an asset without reliable data? With a paper-based or spreadsheet system, the answer is: they can't. They rely on gut feelings and anecdotes.

Consider a recurring failure on a critical CNC machine. The paper work orders are filed away, maybe. The notes on them are inconsistent. One technician might write "replaced bearing," while another writes "fixed motor noise." Was it the same bearing? Was it a drive-end or non-drive-end bearing? What brand was used? Was there evidence of misalignment? Without a centralized digital history, it’s impossible to connect the dots. You treat the symptom every time, but you never discover the root cause.

This lack of accessible history makes tracking meaningful KPIs (Key Performance Indicators) a fantasy. What’s your true Mean Time to Repair (MTTR)? How is your Mean Time Between Failures (MTBF) trending on your most critical assets? Answering these questions with spreadsheets requires hours of manual data entry and manipulation, so it rarely gets done. You’re flying blind, unable to identify bad-actor assets that are silently bleeding your budget dry or justify a capital request for a replacement with hard data. The knowledge is siloed in individual minds and disorganized files, not in an accessible system that benefits the entire organization.

The Hidden Drain of Inefficient Inventory Control

The maintenance stockroom is often ground zero for operational waste. Without a system connecting parts to assets and work, facilities typically find themselves in one of two costly situations.

The first is the "just-in-case" graveyard of parts. Fearing stockouts, they over-order. Capital is tied up in spares that may sit on a shelf for years, becoming obsolete or even degrading over time. The stockroom is full, but you can never find what you need. The second, and often more damaging, situation is the chronic stockout. A critical production line goes down. The technician diagnoses the problem in 20 minutes—a failed variable frequency drive. But the part isn't in stock. Now, what should have been a one-hour repair turns into an 8-hour (or multi-day) ordeal. Technicians waste valuable wrench time searching for parts, a manager spends hours on the phone trying to find a local supplier, and the company pays a fortune for expedited, next-flight-out shipping.

Effective inventory control is impossible in this environment. There are no accurate counts, no automated reorder points, and no way to track where parts are being used. This chaos directly extends equipment downtime and inflates maintenance costs through emergency purchases and carrying costs for unnecessary stock.

The CMMS Transformation: From Firefighting to Strategic Asset Management

Implementing a modern CMMS is about fundamentally changing the way maintenance is planned, executed, and measured. It’s a cultural shift, enabled by technology, that moves the entire department from a reactive cost center to a proactive partner in production and profitability.

Building a Proactive Maintenance Culture with Preventive Maintenance (PM)

The core of this transformation lies in establishing a robust preventive maintenance program. A PM program is about taking control. It’s about servicing equipment on your schedule, not the equipment's schedule. A CMMS is the engine that drives this.

Instead of relying on a shared calendar or a binder full of checklists, a CMMS automates the entire process. PMs for a packaging line’s conveyor system can be scheduled to trigger automatically every 500 runtime hours, captured directly from a PLC. Or, simpler calendar-based PMs, like quarterly lubrication routes, can be set up to generate work orders for the appropriate technicians automatically.

The work orders themselves are no longer vague instructions. They contain detailed, step-by-step procedures, safety checklists (like Lockout/Tagout), required tools, and a list of necessary parts. This standardization ensures the job is done correctly and consistently, no matter which technician is assigned. By systematically performing these tasks, you catch problems before they become catastrophes. You replace a worn belt during a planned 20-minute window instead of reacting to it snapping and taking out a sensor with it, causing a four-hour outage. This proactive approach is the single most effective strategy for extending the asset lifecycle and maximizing the return on your capital investments. Modern, user-friendly systems like MaintainNow are designed to make setting up these complex, nested PM schedules straightforward, taking the administrative burden off supervisors so they can focus on managing the work itself.

Optimizing Workflows and Unleashing Wrench Time

Think about the journey of a typical work request. An operator notices an unusual vibration on a pump. How do they report it? They have to find their supervisor, who then has to find a maintenance planner or write it on a whiteboard, where it might get overlooked. It's a process full of delays and potential for lost information.

A CMMS digitizes and centralizes this entire workflow. The operator can submit a request from a plant-floor kiosk or even their own mobile device, complete with photos or videos of the issue. The request instantly appears in the maintenance planner’s queue for approval and scheduling. Once it becomes a work order, it’s assigned to a technician who receives a notification on their mobile device.

This mobile capability is a game-changer. Technicians no longer have to walk back to the shop to pick up their next assignment or to look up information. Standing right in front of the asset, they can pull up the work order, view the asset's entire repair history, access attached schematics or OEM manuals, and even scan a QR code on the machine to ensure they have the right equipment. This is where a truly mobile-first platform, like the one found at `https://www.app.maintainnow.app/`, demonstrates its immense value. It drastically reduces travel time and information-gathering time, maximizing the amount of the day technicians spend with tools in their hands—the all-important wrench time. Upon completion, they can log their hours, note the parts used, and close the work order right from their device. The data is captured instantly and accurately. No more deciphering greasy, handwritten notes at the end of the day.

Gaining True Control Over Maintenance Costs and Inventory

To manage costs, you must first be able to measure them accurately. A CMMS becomes the single source of truth for all maintenance-related expenditures. Every work order meticulously tracks the critical cost components:

* Labor: How many hours did each technician spend on the job? What was their trade rate?

* Parts: Which specific parts were pulled from inventory for the repair? What did they cost?

* External Services: Was a specialized contractor brought in? The invoice and details are attached to the work order.

This data automatically rolls up. At a glance, a manager can see the total maintenance cost for a specific asset, an entire production line, or the whole facility over any period. This isn't just about accounting; it's about decision-making. When a 15-year-old air compressor has cost $25,000 in repairs over the last 18 months, the data makes the case for a $40,000 replacement undeniable. You can move from "I think this machine is unreliable" to "This machine's maintenance cost per unit of output is 300% higher than its peers, and its MTBF is trending downward by 15% quarter-over-quarter."

This same data integration revolutionizes inventory control. The CMMS stockroom module is linked directly to the work order system. When a technician logs that they used a specific motor on a work order, the system automatically deducts it from the inventory count. When the on-hand quantity for that motor drops below a pre-set minimum level, the system can automatically generate a purchase requisition for the purchasing department. This prevents stockouts, eliminates the need for manual cycle counts, and provides full visibility into parts usage, helping to optimize stocking levels and reduce carrying costs.

The Ultimate Goal: Driving OEE Through Maintenance Excellence

Everything discussed so far—proactive maintenance, optimized workflows, cost control—ultimately serves a higher purpose in a manufacturing environment: improving Overall Equipment Effectiveness. OEE is a composite metric that measures the percentage of planned production time that is truly productive. It's calculated as: OEE = Availability x Performance x Quality. Maintenance has a direct and profound impact on all three components.

How Maintenance Impacts Availability, Performance, and Quality

* Availability: This is the most obvious link. A robust PM program, powered by a CMMS, directly reduces unplanned downtime. When machines run when they're supposed to run, the Availability score goes up. A CMMS helps you track and analyze downtime reasons, so you’re not just fixing things faster (improving MTTR) but also making them fail less often (improving MTBF).

* Performance: This metric measures how close your machines are running to their ideal or designed speed. Minor stops, reduced speed, and idling all hurt the Performance score. A well-maintained and properly calibrated machine is capable of running at its full potential. PM tasks like cleaning, lubrication, and calibration, all tracked and scheduled in a CMMS, ensure that assets don't suffer from the small, cumulative issues that force operators to slow them down to avoid a fault or a jam.

* Quality: This component tracks the percentage of good parts produced. Defects, scrap, and rework all detract from the Quality score. The connection to maintenance can sometimes be less obvious but is just as critical. A misaligned machine, a worn tool, or an improperly tensioned conveyor can all lead to out-of-spec products. A CMMS ensures that the precision tasks required to maintain quality standards are performed on schedule and to the correct specification.

By systematically improving all three OEE factors, maintenance transitions from being viewed as an overhead expense to a direct contributor to plant capacity and profitability.

From Gut-Feel to Data-Driven Decisions

The reporting and analytics capabilities of a CMMS are what elevate a maintenance department from a reactive repair crew to a strategic reliability team. Instead of relying on intuition, managers can now use hard data to guide their actions.

Dashboards can provide a real-time view of plant health: PM compliance rates, work order backlog, and critical asset status. Reports can identify trends that would otherwise be invisible. Are failures of a certain component increasing across multiple machines? This might point to a faulty batch of spare parts or an issue with installation procedure. Is one shift completing significantly fewer work orders than another? This might indicate a need for more training.

This data is the foundation for a continuous improvement loop. It allows for formal Root Cause Analysis (RCA) on significant failures. It enables smarter resource allocation, focusing technicians and budget on the most problematic assets. It is through this analytical lens that organizations can truly optimize their maintenance strategy, making informed choices about where to invest time and money for the greatest return. Platforms like MaintainNow are designed with this in mind, presenting these complex KPIs in simple, visual dashboards that don't require a degree in data science to understand.

Conclusion

The transition away from clipboards and spreadsheets is no longer a matter of preference; it's a matter of competitive survival. The inherent inefficiencies of manual, paper-based systems—the rampant unplanned downtime, the invisible inventory waste, the lack of data for decision-making—create a constant drag on productivity and profitability. The "way it's always been done" is now a direct path to being outpaced by more agile, data-driven competitors.

A modern CMMS is the foundational technology for building a culture of reliability. It provides the structure to escape the reactive firefighting cycle, the tools to optimize workflows and control maintenance costs, and the data to strategically improve the asset lifecycle and drive OEE to world-class levels. It empowers technicians with the information they need at their fingertips and gives managers the visibility required to lead effectively.

For manufacturing leaders, the question is no longer *if* a CMMS is necessary, but how quickly an intuitive, mobile-first system can be implemented to stop the bleeding from operational inefficiencies. The tools to take control, to transform maintenance from a perceived liability into a powerful strategic advantage, are more accessible and easier to deploy than ever before. In an industry where every minute of production counts, arming your team with the right system is one of the most valuable investments you can make.